Material requirements planning (MRP) software helps manufacturers plan, forecast, and manage production by ensuring materials and resources are available when needed. It plays a critical role in industries like food and beverage, where traceability and compliance must be tightly controlled. Whether you're scaling up or moving away from spreadsheets, the right MRP system can align your resources, strengthen traceability, and improve overall workflow. In this guide, we'll review the best MRP software, their features, and how an MRP can support your company.

What is MRP Software?

MRP software is designed to help manufacturers plan and manage production efficiently. It identifies the resources needed, estimates quantities, and determines when they’ll be required, all to meet production schedules and increase productivity. It ensures that businesses have the right resources at the right time. That way, manufacturers can minimize shortages, reduce waste, and maintain effective production schedules.

ERP vs. MRP

Enterprise Resource Planning (ERP) software is a comprehensive and integrated platform that businesses can use either on-premises or in the cloud. It manages all aspects of manufacturing and distribution by connecting finance, human resources, supply chain, and production to a central accounting system. This automation enables businesses to simultaneously improve visibility across departments and make faster, more informed decisions.

While both MRP and ERP aim to improve operational efficiency, they differ significantly in scope. MRP primarily deals with manufacturing demands, whereas ERP covers the entire business. An MRP functions as a key component of an ERP system, and an ERP builds upon MRP by linking production planning to broader business functions, including accounting, customer management, and supply chain operations.

Today, most businesses integrate ERP systems with MRP tools to gain full visibility and control, which is essential for staying competitive in a rapidly changing market.

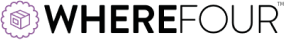

1. Wherefour

Wherefour is a food and beverage manufacturing platform built with traceability at its foundation. It connects production, inventory, and compliance in one system, giving manufacturers control across every stage of their operation.

The platform makes it easy for manufacturers to avoid guesswork in inventory planning. Its standout “What If?” function lets you enter products or formulas with your target production levels and instantly shows whether you have enough materials to meet demand. If you’re short on anything, Wherefour tells you exactly what to reorder and even gives you an estimated cost based on your current inventory cost.

Beyond forecasting, Wherefour delivers enterprise-grade MRP capabilities with just one click. It creates a full material requirements plan using real-time data from across your account, including future levels, inventory levels, open purchase orders, production timelines, and supplier lead times. This provides a clear picture of what is running low, when to reorder, and how to meet customer demand without overstocking.

Best for: Manufacturers seeking to stay ahead by accurately predicting inventory needs, streamlining purchasing processes, and optimizing production efficiency

Features

● Start-to-finish traceability with automatic lot tracking, full audit trails, and instant recall reports

● One-click, enterprise-grade MRP planning with real-time data

● Cloud-based compliance storage with mobile uploads and secure 24-hour access

● Direct integrations with Shopify, ShipStation, LeafLink, and SPS Commerce

● GS1, Code 128, and Code 93 barcode generation for products and pallet labels

● Easy inventory transfers between facilities with user tracking, custom picklists, and linked account controls

● Visual PDF editor for custom pick sheets, bills of lading, and warehouse documents.

● Configurable and brandable wholesale ordering portal

Pros

● User-friendly and easy access to necessary modules

● Easy production planning, tracking, and inventory recording

● Amazing customer service team

Cons

● Initial learning curve for new features, but made easier by responsive customer support

Pricing: Wherefour provides custom price quotes depending on your company’s specific needs.

Schedule a free demo with Wherefour today.

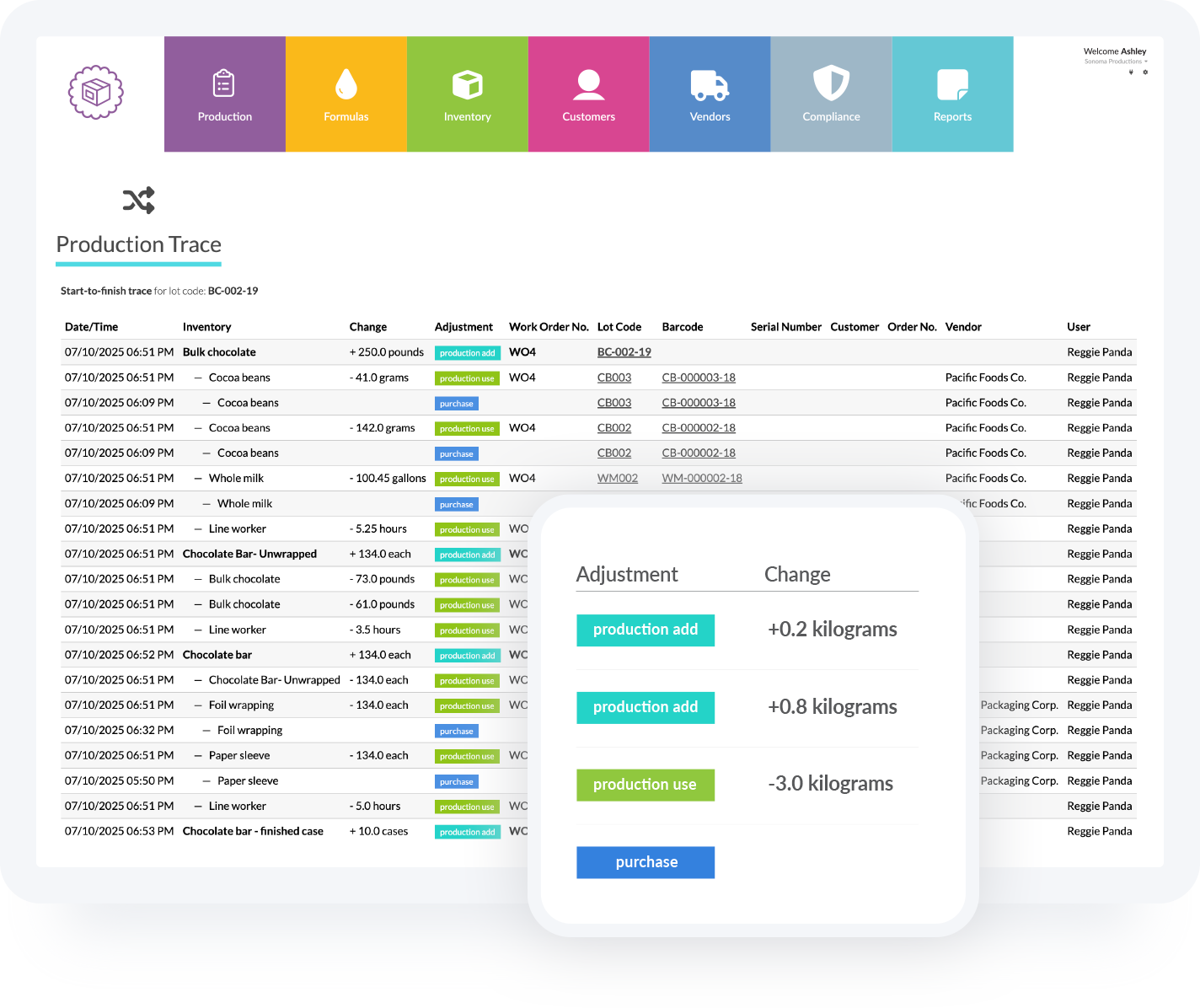

2. Fishbowl

Fishbowl connects manufacturing, inventory, ecommerce, sales, CRM, and accounting in one platform. It enables both repetitive and discrete processes with configurable options. The platform enables manufacturers to manage operations without the high costs associated with traditional MRP systems.

Best for: QuickBooks and Xero users

Features

● Dedicated Bill of Materials (BOM) module to remove manual steps and guesswork

● Automated manufacturing and work orders for greater efficiency

● Flexible configuration to support complex, multi-location operations

● Centralized storage for contracts and key documents

● WIP and finished-goods cost tracking to set accurate profit margins

Pros

● Knowledgeable customer support

● Data extraction and custom reporting

Cons

● Customizing useful reports can be costly, and the reporting system is difficult to navigate

Pricing: Quotation-based pricing model, free demo available on request.

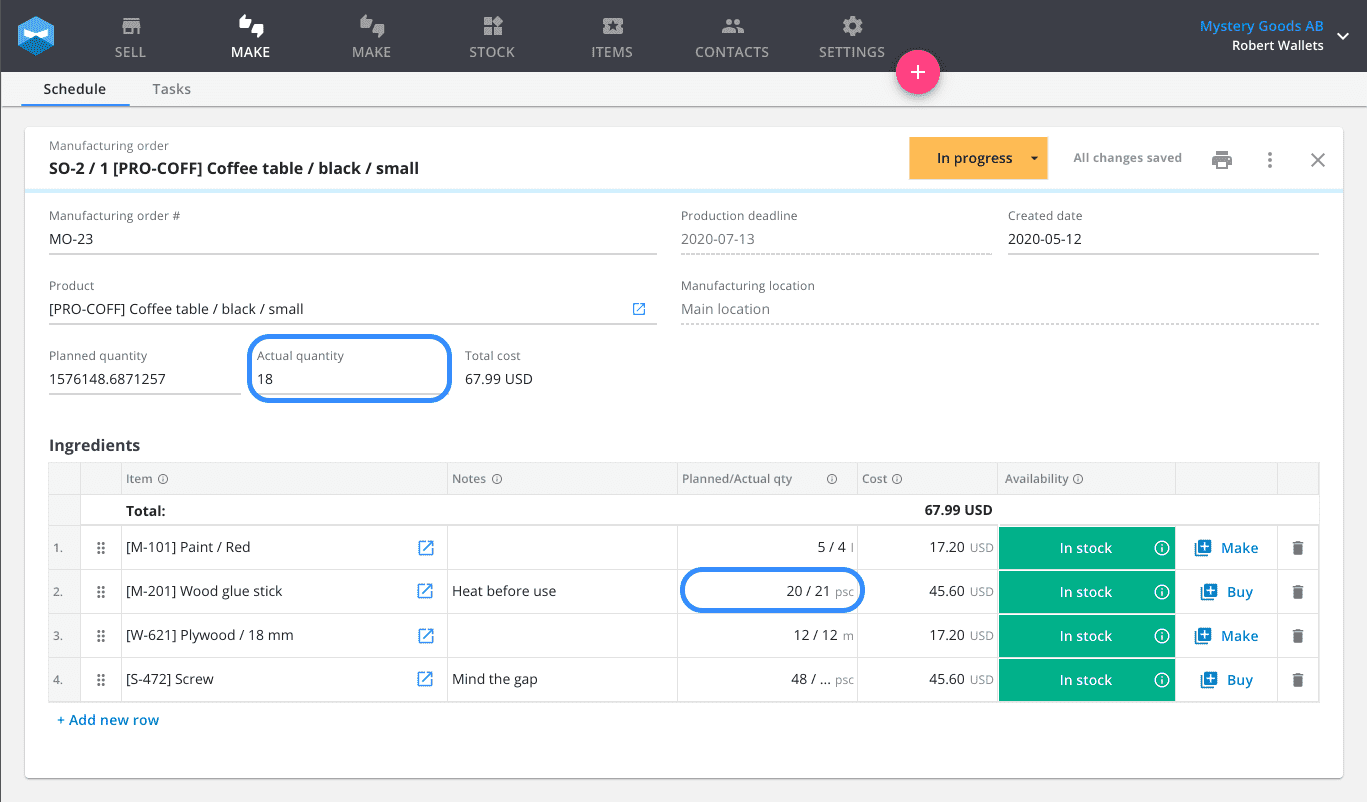

3. Katana MRP

Katana is a cloud-based MRP designed for small to mid-sized businesses. It combines production planning, inventory tracking, and sales order management into a single platform. It provides real-time inventory updates, purchase order handling, and integration with tools like Shopify, WooCommerce, Xero, and QuickBooks Online.

Best for: Small to mid-sized manufacturers

Features

● Real-time inventory insights to reduce waste and carrying costs

● Purchase order tracking to prevent stockouts and improve procurement

● Forecasting tools to maintain optimal stock and meet demand

● Connected sales channels for faster order processing and better control

● Business performance analysis tools for clear insights into operational and product costsPros

● Clear visual stock levels on manufacturing and sales orders

● Stock updates with easy undo options

Cons

● Serial tracking limitations

● Lack of integration with Google Sheets for CSV downloads

Pricing:

● Standard: $359/month ● Professional: $799/month ● Professional plus: $1,799/month

4. MrPeasy

MRPeasy is a cloud-based MRP software for small manufacturers that includes features for production planning, scheduling, capacity management, order tracking, and job reporting. The system calculates product costs and lead times, converts customer orders to manufacturing orders with a single click, and generates purchase orders for out-of-stock items.

Best for: Small manufacturers looking for a cloud-based system

Features

● Real-time inventory and production scheduling

● Built-in CRM, procurement, and order management

● Advanced Bill of Materials (BOM) tools

● Serial number tracking of products and components

● Manufacturing Order tracking from planning to completion

Pros

● Intuitive interface that's easy to navigate, even for beginners

● Responsive customer support team

Cons

● Master forecasting feature can be tricky to navigate, especially for beginners

● Limited customization in reports

Pricing

● Starter: $49/user/month

● Professional: $69/user/month ● Enterprise: $99/user/month ● Unlimited: $149/user/month

5. xTuple

xTuple is an ERP platform for manufacturers. Its MRP tools facilitate production planning, purchasing, and inventory control. The system keeps track of what is needed and when, with the goal of reducing excess inventory and avoiding shortages.

Best for: Small to mid-sized manufacturers and distributors

Features

● Detailed BOM for accurate production planning

● Purchase order management with tracking tools for streamlined procurement

● Built-in Reporting and KPI Dashboards to track performance

● Multi-level MRP for planning materials

● Production schedule to align manufacturing with demand forecasts

Pros

● Flexible system that supports various manufacturing processes

● Highly customizable reporting tools

Cons

● Support can be pricey, confusing, and often unhelpful

● Not very intuitive—data connections between modules are weak

Pricing: Pricing not available on its website

6. Odoo

Odoo is an ERP platform that allows businesses to run their operations from a centralized system. Its MRP applications include manufacturing, quality, maintenance, and repairs. You can also integrate tools such as CRM, sales, inventory, and accounting, as everything runs from a single database, ensuring teams stay in sync.

Best for: Businesses that want a collection of business apps

Features

● Available in two editions: the free, open-source Community version and the Enterprise version

● No vendor lock-in, your data stays yours with open format and flexible hosting

● Automates tasks and creates custom screens and reports

● Pricing is based on one all-inclusive rate per user ● An intuitive user interface with smart filters

Pros

● Seamless integration between apps

● Easy to use even for non-technical users

Cons

● Support quality depends on your contract level

● Workflow management can be challenging initially

Pricing

● One app free

● Standard: $8.95 ● Custom: $13.60

7. DelmiaWorks

DELMIAWorks is an end-to-end ERP system designed with a “shop floor first” approach. It helps mid-sized manufacturers by connecting production, planning, inventory, and finance, providing visibility into manufacturing operations.

Best for: Mid-sized manufacturers that need close integration between shop floor and business systems

Features

● Real-time production monitoring for faster decisions

● Customer, supplier, and partner support management

● Industry-specific and recipe reformulation tools tailored to industry needs

● Advanced scheduling engine with sequencing and wait time logic

● Compliance features for FDA, FSMA, GFSI, HACCP, and SQF regulations

Pros

● Has an in-house EDI team that supports implementation

● Built-in MES functionality provides visibility and reduces reliance on third-party tools

Cons

● Full implementation can be complex and time-consuming

● Built-in reports often feel outdated and lack customization for module-specific needs

Pricing: No public pricing is available.

8. Total ETO

Total ETO is an ERP and MRP system specifically made for engineer-to-order and custom manufacturers. It helps manage job-specific Bills of Materials (BOMs) and works with Computer-Aided Design (CAD) tools like SolidWorks and Inventor, and it connects with accounting software like QuickBooks and Sage. It also covers purchasing, inventory, and routing for industries like aerospace, medical, and food manufacturing.

Best for: Manufacturers seeking ERP capabilities in the custom design sectors

Features

● Advanced production scheduling for balanced workloads and optimized resource utilization

● Unified ERP and CRM for shared customer, product, and order information

● Real-time inventory tracking with barcode scanning and cycle counts

● Detailed cost tracking for materials, labor, and overhead in manufacturing

● BOM and revision management for accurate and updated production details

Pros

● Straightforward entry of bills of materials

● Easy tracking of assigned projects for entry and expediting

Cons

● Limited document linking options outside the sales order section

● Restricted user administration features

Pricing: Pricing isn’t available on its website.

9. Fulcrum Pro

Fulcrum is cloud-based manufacturing software built to connect your shop with live data. It replaces traditional ERP, MRP, and MES systems to help manufacturers streamline operations. It allows you to track jobs, materials, and workflows all in one place.

Best for: Small to mid-sized manufacturers

Features

● Real-time inventory tracking as orders and schedules change

● Priority dashboard showing low inventory and delayed jobs to keep production on track

● One-click approval, scheduling, and release of multiple jobs

● AI-generated BOMs from images or files to speed up quoting

● System integrations to prevent duplicate data entry

Pros

● Easy job tracking and costing with flexible travelers

Cons

● Users find the complex implementation process challenging

● Some back-end interface elements are cumbersome to use

Pricing: Pricing isn’t listed on its website

10. SOS Inventory

SOS Inventory is a cloud-based inventory management software for small to mid-sized businesses. It integrates with QuickBooks Online to manage inventory, orders, and manufacturing. It removes manual steps and streamlines operations in industries such as wholesale, retail, and e-commerce

Best for: Small to mid-sized businesses that use QuickBooks Online

Features

● QuickBooks Online integration to reduce duplicate data entry and save time

● True sales order generation to track product and service sales

● Material receiving, order shipping, and stock transfers between locations

● Serial number tracking with full cost history monitoring

● Assembly building with real-time work-in-progress tracking

Pros

● Easy to learn and use

● Users can access inventory and manage orders from anywhere

Cons

● Customized changes can take a long time to implement

● Inconsistent syncing with QuickBooks Online due to backend issues

Pricing:

Companion: $64.95/month Plus: $129.95/month Pro: $179.95/month

11. Mar-Kov

Mar-Kov’s MRP software helps batch manufacturers connect inventory, sales, and production in real-time. It automates purchasing, prevents stockouts, and reduces delays by syncing supply chain activities. The system enables data-based decisions to keep operations running smoothly.

Best for: Batch and process manufacturers

Features

● Purchasing and production planning based on real-time demand

● Reorder automation using consumption rates, safety stock, and lead times

● Material planning alignment with production to reduce downtime

● Real-time tracking of open purchase and shipping orders

● Purchase order generation based on demand, rules, and vendor data

Pros

● Integrates smoothly with SOPs and CPs for HACCP plans

● Accurately tracks and traces orders, lots, shipping, and inventory

Cons

● Requires a lot of initial data setup, which can be time-consuming for new users

● Requires a steep learning curve

Pricing: Pricing not available on its website.

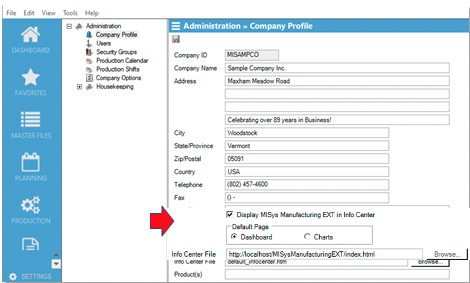

12. MiSys

MISys offers MRP software built for small to medium-sized manufacturers looking to simplify how they manage operations. It provides tools for inventory management, production control, and material planning in one integrated system. It integrates with accounting platforms such as QuickBooks (desktop and online), Sage 50 (US and Canada), Sage 300, and Sage Intacct to enable production workflows.

Best for: Small to medium-sized manufacturing firms

Features

● Manufacturing inventory and work-in-process (WIP) tracking

● Detailed stock status records for all inventoried items

● Multi-level Bills of Material (BOM), with full explosion up to 16 levels

● Costing flexibility with standard, average, LIFO, or FIFO methods

● Batch-oriented or direct entry of all stock transfer transactions.

Pros

● Inventory checking and thorough history analysis

Cons

● Customization cost is high, and the system architecture is old-fashioned

● Reports are in raw format, and the interface may be difficult for beginners to use

Pricing: Pricing isn’t listed on its website.

How Can MRP Software Support Your Company?

MRP software helps you take control of your production process by organizing materials, managing inventory, and streamlining scheduling. Instead of juggling spreadsheets or dealing with last-minute shortages, you can plan with real-time data. Here are the main ways MRP software can support your operations:

1. Tracks material requirement

MRP software tracks the materials you need—when and how you need them—all based on real-time demand, sales orders, and production plans. It analyzes data from your production plan to determine the quantity and cost of materials and components (also known as inventory or stock) required to meet consumer demand. It also automatically determines requirements based on your bill of materials, current stock levels, lead times, and reorder points. Instead of relying on manual checks, you can obtain fast, accurate forecasts to prevent both shortages and excess inventory.

2. Manages resources and assets

MRP software does more than just track materials, it helps you make better decisions about equipment, labor, and operational assets. When raw materials are scarce or unavailable, the system promptly alerts you, allowing you to adjust production plans, reassign resources, or source the necessary materials without delay.

In the background, MRP software coordinates various moving parts such as scheduling machines, assigning labor, and flagging capacity limits early. You’ll know when to buy, rent, or allocate equipment, as well as when to hire extra workers to keep production running smoothly. With this level of insight, you can maximize efficiency, avoid last-minute scrambles, and make the most of your existing resources.

3. Optimizes purchase decisions

Smart purchasing decisions start with accurate, real-time data. With MRP systems, manufacturers can make better, faster, and more cost-effective purchasing decisions. The software utilizes key factors like consumer demand, lead times, on-hand inventory, and open purchase orders to generate precise buying suggestions. These automated prompts help planners and schedulers decide when and what to buy. In fast-paced manufacturing environments, particularly those with multi-level BOMs, this level of intelligent planning isn’t just helpful; it’s essential.

4. Improves production efficiency

Production efficiency is dependent on timing, accuracy, and resource coordination. MRP helps manufacturers stay ahead by ensuring that the right materials are readily available when needed and in the correct quantities. It analyses production schedules, customer orders, and inventory levels to develop a clear, actionable plan for each production order. This plan outlines the raw materials, components, and subassemblies required, along with the corresponding quantities and delivery schedule. As a result, you get streamlined workflows, reduced downtime, and a more efficient path from raw materials to finished goods. If a beverage producer needs to fulfill a sudden order for 10,000 bottles of juice, the MRP system calculates how much fruit, sugar, packaging, and labor are required. It then aligns supplier deliveries and production schedules to ensure the demand is met on time.

5. Controls inventory better

MRP systems help manufacturers manage inventory by providing real-time visibility into what’s in stock, what’s on order, and what’s needed for future production. The system continuously analyzes sales orders, production needs, and lead times to avoid both overstocking and stockouts. This results in lower holding costs, fewer storage issues, and smoother operations overall.

6. Reduces costs

MRP software helps you reduce manufacturing costs by increasing operational efficiency. First, it prevents overstocking and understocking. You order exactly what you need, when you need it, keeping inventory costs low and increasing cash flow. It also reduces production delays. Better planning ensures that the right materials and resources are always available. On the purchasing side, MRP enables you to consolidate orders, schedule purchases, and negotiate more favorable terms with suppliers, which can significantly increase your profit margins.

7. Fills orders fast

Speed matters in manufacturing, and MRP software helps you deliver on time. By aligning inventory levels, production schedules, and customer demand, you can ensure that the proper products are always available when orders arrive. You can easily track what’s in stock, what’s being produced, and what needs to be shipped. With a streamlined process, you not only meet deadlines but also build trust and loyalty with your customers.

8. Maintains compliance

Compliance comes with additional costs. Manufacturers have to invest in tools, technology, and process changes to meet regulatory standards. For example, if a law prohibits the use of a specific material, your team may need to explore alternatives, which could increase material costs and disrupt your supply chain. MRP systems help you manage these challenges by providing the visibility and control you need to adapt quickly and minimize disruptions while maintaining full compliance. This is especially important when dealing with food labeling regulations and other industry-specific requirements.

Key MRP Software Features

Here are some features you should look for when choosing an MRP software for your business:

Bill of materials: Look for software that can create detailed and accurate Bill of Materials

(BOMs) outlining each component needed for production. It should also integrates with

your inventory and procurement tools to ensure materials are available on time.

Inventory and order management: Choose a system that monitors raw materials and

finished goods in real-time to prevent stockouts and excess inventory. It should offer automated reordering and automatic alerts to ensure a seamless flow of materials without interruption.

Production scheduling: Prioritize tools that help you develop a clear and realistic

production plan based on available materials, labor, and resources. It should take into account production and lead times to ensure everything runs on schedule.

Quality and quote management: Consider platforms that collect live data on labor,

materials, and timelines to support accurate quoting. They should also enforce quality standards throughout the production process.

Supply chain management: Make use of solutions that give you visibility across the entire

supply chain, from raw materials to customer delivery. This ensures suppliers, distributors, and customers stay aligned.

Demand Forecasting: Seek out software that helps you predict what your customers will

need and when they will need it. MRP uses actual sales or forecasted demand to determine the right materials and quantities for production.

Real-time reporting: Consider platforms that provide instant updates on inventory levels,

production status, order progress, and more, all in one place. With access to current data, you can make smarter decisions and respond to any issues before they get worse.

Choose the Best MRP Software

Choosing the right MRP software is one of the most important decisions a manufacturing company can make. While several tools are available with similar features, not all of them are specifically tailored to the needs of manufacturers and the issues they encounter on a daily basis.

Wherefour is a modern cloud-based MRP software built specifically for process manufacturers. It allows you to manage real-time inventory, track raw materials and finished goods, schedule production, ensure compliance, and generate accurate quotes all through a single, mobile-friendly interface.

Because it is designed for manufacturers, Wherefour has been set up to meet industry-specific requirements, such as material traceability, supplier performance tracking, and demand forecasting. Whether you’re a growing business or already manage multiple production lines, Wherefour provides the clarity, control, and confidence you need to run your operations efficiently.

MRP Software FAQs

What's the difference between full-suite and best-of-breed MRP software?

Full-suite MRP software provides an all-in-one solution from a single vendor. It integrates multiple business operations into a single system, including inventory, production, accounting, and human resources. Its purpose is to cover a wide range of needs under one roof. Best-of-breed MRP software concentrates on performing a single task exceptionally well. It’s designed to handle specific tasks, such as material planning or production scheduling, with a high level of precision and customisation. You can then integrate it with other specialized tools to create a customized system tailored to your workflow. The primary difference lies in flexibility and focus. Full-suite solutions offer convenience and centralization, while best-of-breed solutions deliver depth and specialization. Your decision should be based on your priorities, the tools you already use, the level of flexibility you need to grow, and your customer experience goals. How much does MRP software cost?

The cost of MRP software varies based on several factors, including your company size, number of users, industry, required features, and whether you choose a cloud-based or on-premise solution. Custom integrations, advanced reporting, and regulatory compliance tools also impact pricing. What are the upcoming trends surrounding MRP software?

MRP software is shifting toward cloud-based platforms that offer real-time access, easier updates, and better scalability. Automatic updates reduce IT overhead and keep systems current without manual effort. Developers are also integrating AI and machine learning to improve demand forecasting and decision-making. These tools help analyze usage patterns, optimize inventory levels, and reduce waste. The Internet of Things (IoT) is also growing, allowing manufacturers to track equipment, materials, and production status in real time for better control and faster response to issues.