Be audit-ready at all times with built-in recall and traceability tools.

Recalls (real or mock ones), surprise inspections and supply chain hiccups happen in manufacturing. Planning for the worst is, unfortunately, what well-run companies need to do these days. The COVID-19 situation certainly taught all of us this lesson, in a very painful way.

You need data and a system you can trust. Data that is accurate, easy to access, and available wherever (and whenever) you need it. Even if all you’ve got on hand is your mobile phone and a cellular connection. Because, let’s face it, disasters never happen when we’re actually ready for them.

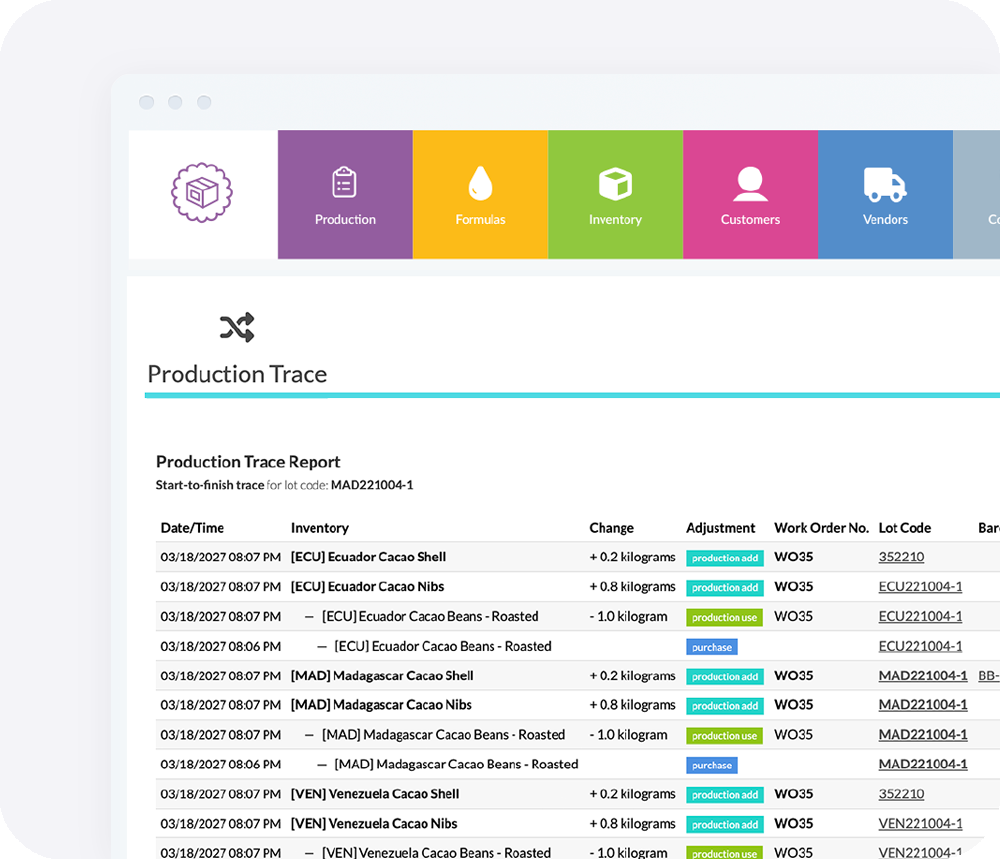

Unlike run-of-the-mill inventory management tools, we built traceability into the foundation of our platform. That means that everything is tracked and traced in glorious, lot-coded and costed detail. So when you need it, that data is there just waiting for you at the click of a button.

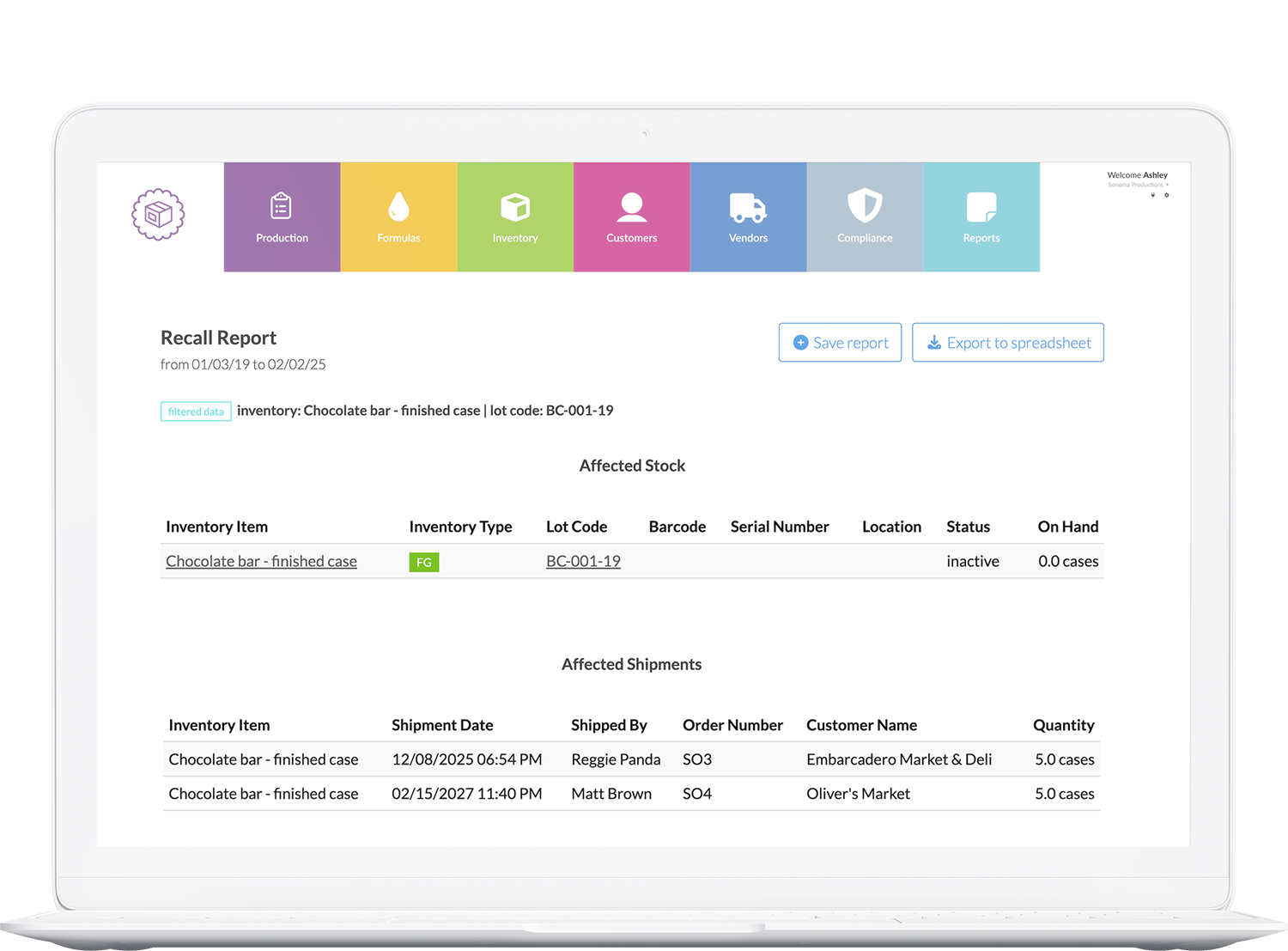

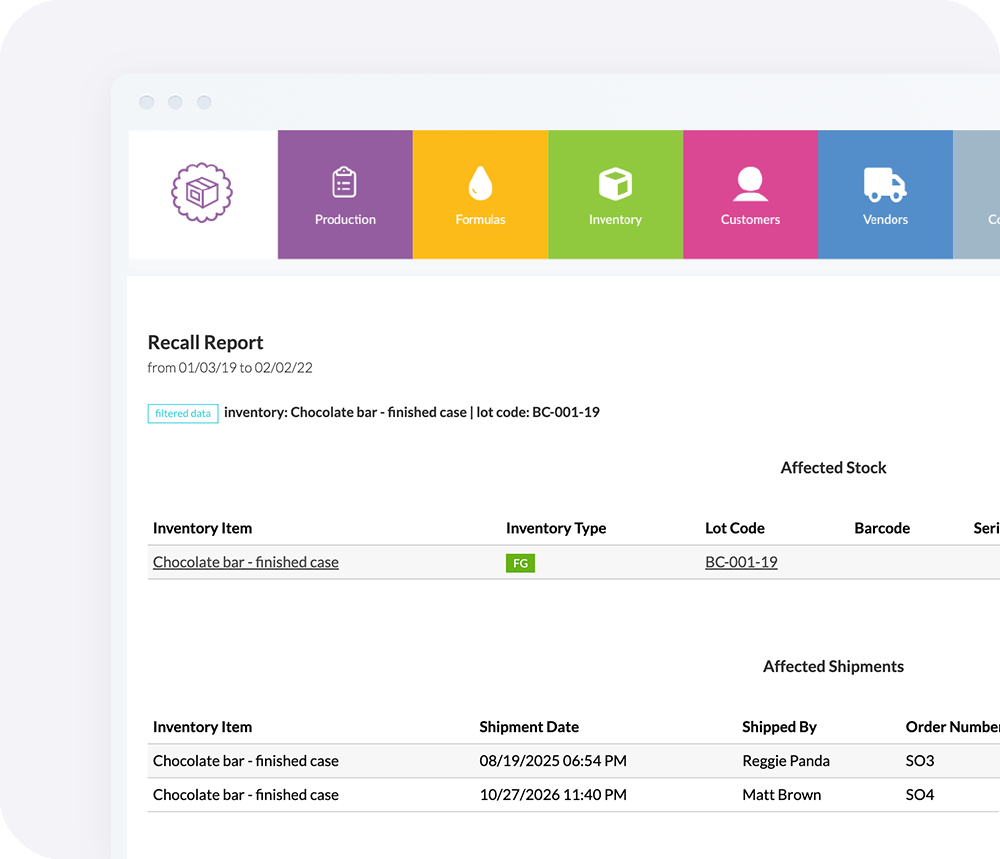

Choose a recalled inventory item and with one click generate a full report of how much you still have on hand and how much went to customers. Perfect for acing your next mock recall or showing that large new potential customer that you are ready for action!

Find the data you need, quickly.

Find the data you need, quickly. Manage your business from wherever you are and on whatever device you want: desktop, laptop, tablet, or phone.

Manage your business from wherever you are and on whatever device you want: desktop, laptop, tablet, or phone. Prove that the data is accurate. Wherefour’s traceability foundation and unbreakable activity log mean that no data can "disappear" or be modified without an audit trail.

Prove that the data is accurate. Wherefour’s traceability foundation and unbreakable activity log mean that no data can "disappear" or be modified without an audit trail. Export your data to convenient formats like Excel or CSV so you can provide it to key customers, suppliers or officials when there is an issue.

Export your data to convenient formats like Excel or CSV so you can provide it to key customers, suppliers or officials when there is an issue. Integrate with other systems your business uses (over 5,000 other platforms) and automate data flows to make running your business even easier.

Integrate with other systems your business uses (over 5,000 other platforms) and automate data flows to make running your business even easier.