Following the recent news that Impossible Burger, the top-funded plant-based food company, is struggling to keep up with consumer demand shows that success doesn’t always come without chaos.

The giant fake meat manufacturer has just announced that they’re short on meat and are asking consumers to call ahead where they usually get their product to see if it’s in stock. In a swift response to the shortage the company has gone to the extreme by reassigning office workers to work 12-hour shifts in their factory facility and FedExing shipments directly to their restaurants, which are usually sold through distributors.

The environment described at their headquarters sounds like madness and makes me wonder; Wherefour-Art-Thou Materials Resource Planning?

Fortunately for the fans of Impossible Burger, they are also responding by implementing a new planning system to help them better factor in fluctuations in demand. But whether your company is big or small, there is a point to be made about the importance of resource planning.

What is Materials Resource Planning?

As many people in the manufacturing biz know, Materials Resource Planning (MRP or sometimes referred to as Material Requirements Planning) is used for production planning, scheduling as well as inventory cost and control for better management of manufacturing processes.

This can be a convoluted process in terms of planning anywhere from your facility design to the type of equipment you purchase but, there are also simple ways to help you plan for unexpected or what may seem impossible events so that you’re not having to quickly scramble like in the case with Impossible Foods.

Using an MRP

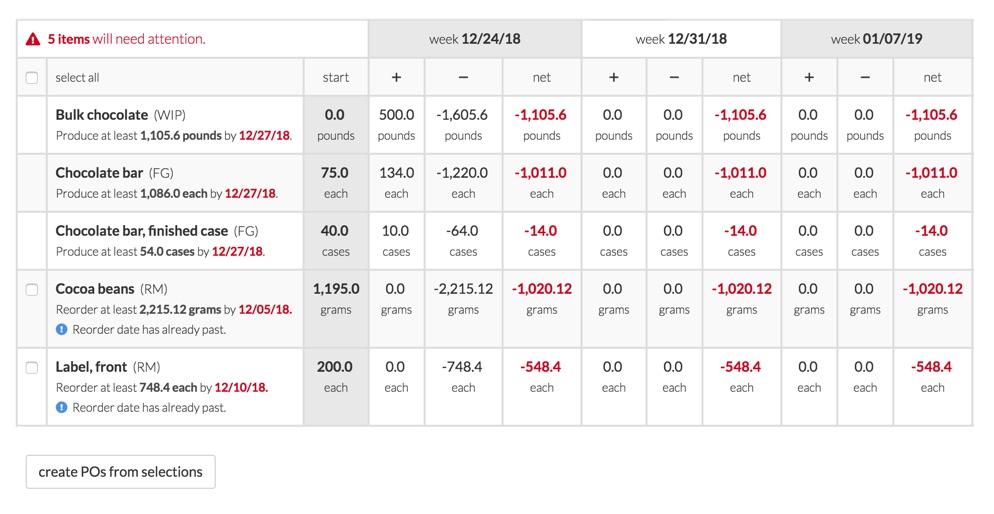

One way to plan for the unexpected is to forecast. A good resource plan should be able to compare current inventory to what has been ordered with upcoming production needs. This includes standing orders and purchase orders to determine whether enough material is available to meet future production requirements.

Additionally, resource planning should flag items and alert you to the lead times required to replenish that inventory and when the order needs to be placed. This can be especially beneficial for businesses that deal with variable customer orders, such as seasonal producers, bakeries and meal delivery services.

And through all of this, your planning should be tracking costs for those ‘what if?’ scenarios. An MRP will do no good if there is no management of cash flow involved.

As an industry expert and creator of Wherefour’s resource planning tool, Matt Brown sums it up perfectly:

“Companies who have to scale quickly spend a lot of cash investing in equipment. If sales shift, all their profit has been used in non-liquid assets. This can put a company out of business quickly and is one of the biggest challenges in running an inventory-based business”

No matter the size or growth model of your business, you want to be prepared to manage and protect your cash flow – a resource plan will help you prepare, manage and respond to the unexpected equipment failures or the unpredictable surge in demand.