End-to-End Food Traceability Software Trusted by Leading Food Brands

Access real-time lot tracking, effortless recall reporting, and complete traceability

from receiving to shipping with Wherefour’s food traceability software.

End-to-End Food Traceability Software Trusted by Leading Food Brands

With Wherefour, there's no need to track stock lots and lot codes manually with paper or spreadsheets anymore. Plus, you’ll have full visibility into every transaction so nothing gets missed during audits or compliance inspections.

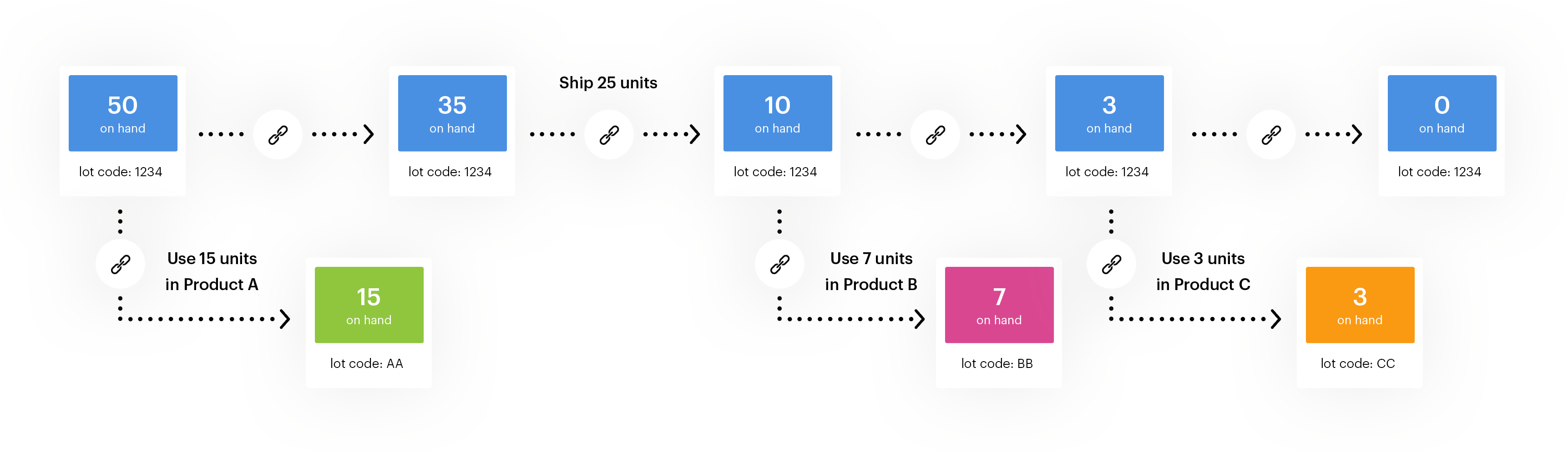

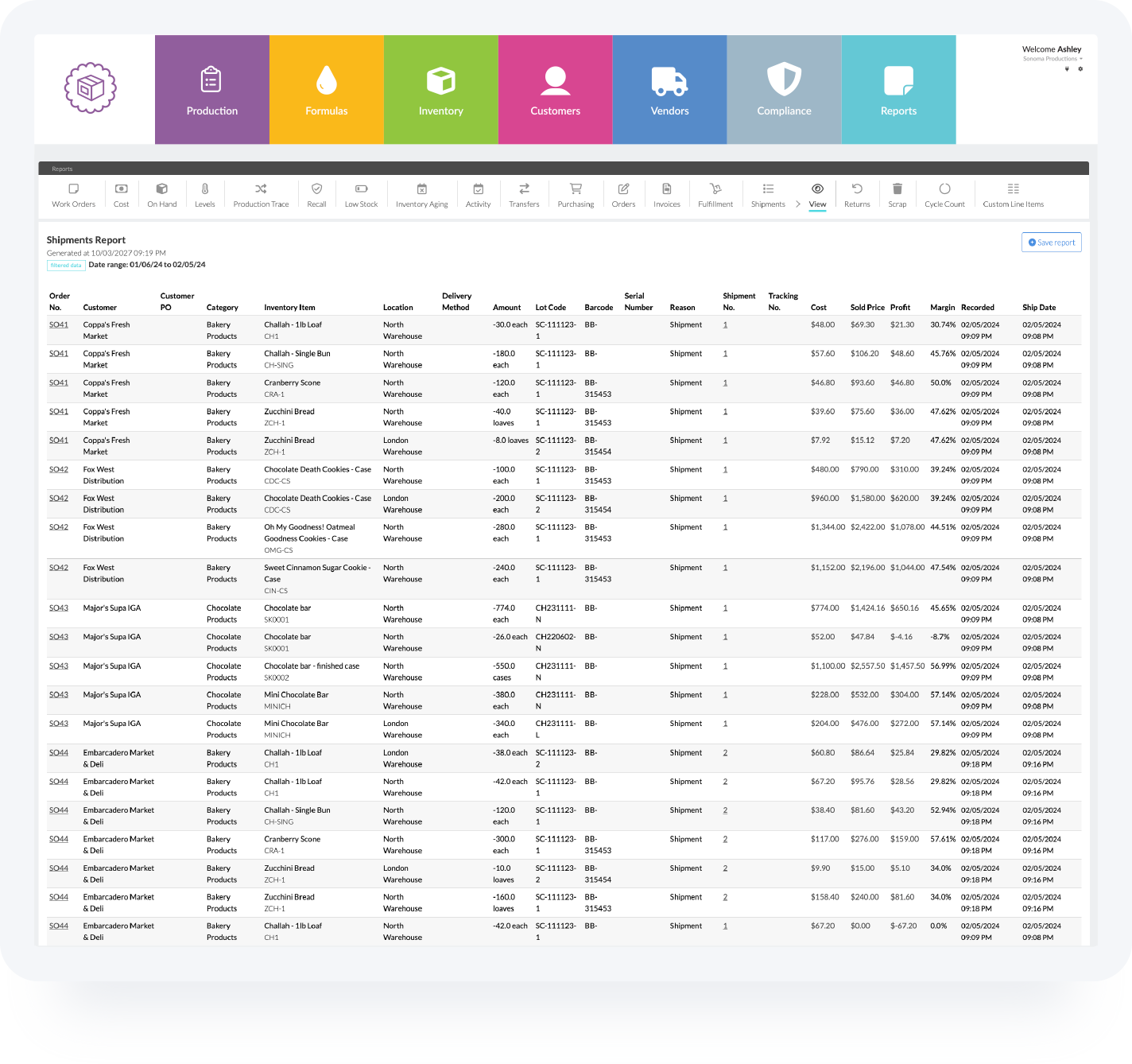

Our platform provides you and your team with one-button lot number tracking—from raw materials through finished goods to the customers who receive them. Pack products into different sizes or containers, automatically generate lot codes, and see what lots and quantities were shipped to customers during a specific date range.

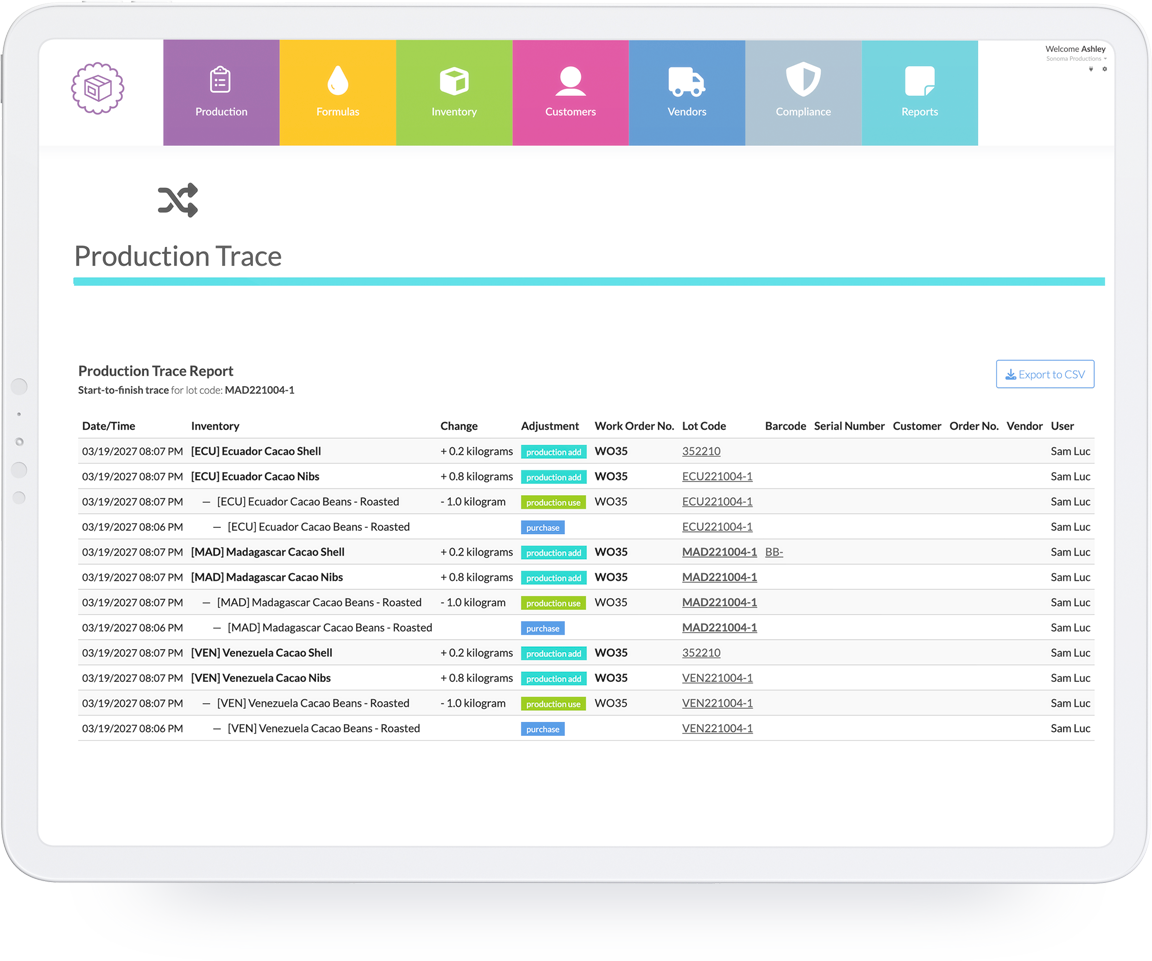

Wherefour’s start-to-finish™ traceability system tracks everything used in your product business.

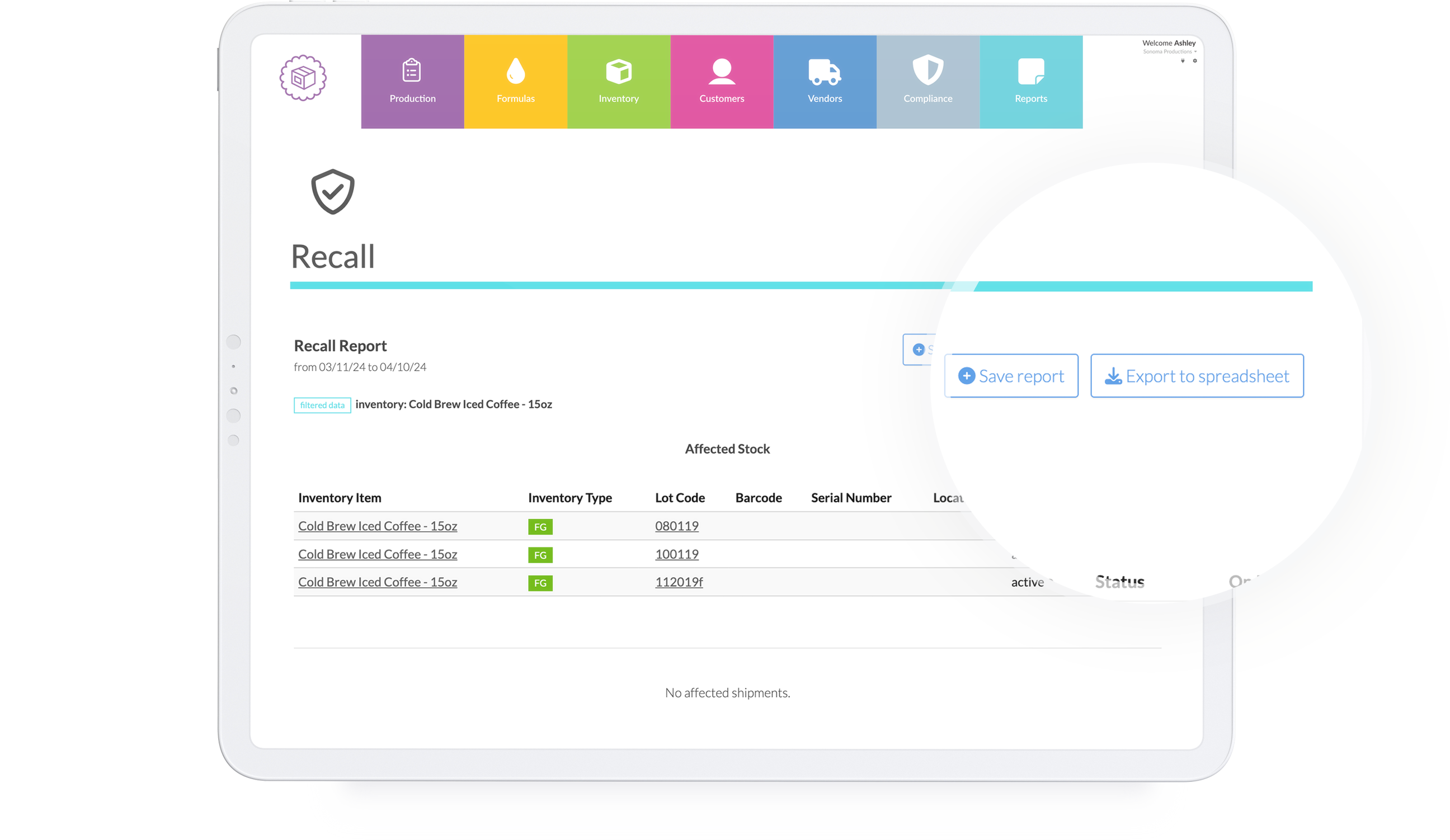

Generate full traceability or recall reports any time by ingredient date range or specific lots of production, including what was shipped to customers. Whether it’s for a surprise audit, mock recall, or real supply chain issue, you’ll have reliable, detailed data at your fingertips. No scrambling, no second-guessing, just instant clarity when you need it most.

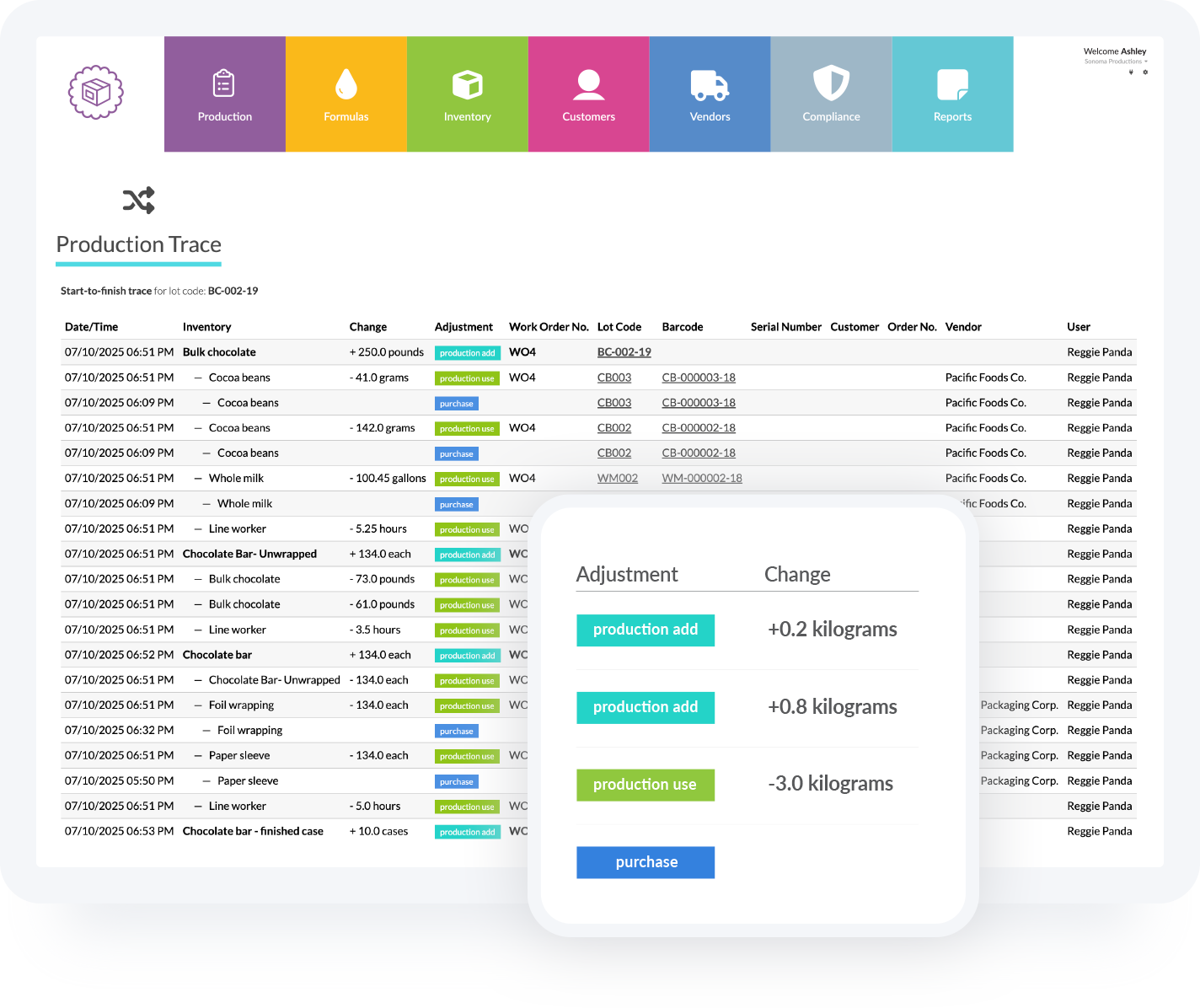

Need to make corrections to a production run? Wherefour automatically adjusts the run using reworked production data and logs every detail. You’ll know exactly which suppliers provided which ingredients, which batches they were used in, and which customers received the final products. No gaps, no guessing, and no manual edits required.

When you ship products via distributors or direct store delivery, Wherefour automatically records the lot codes used. These codes are added to invoices and order records, creating a precise, searchable history. You’ll always know which lots and quantities were sent, to whom, and when, helping you stay recall-ready and audit-compliant without extra admin.

Generate forward, backward, or bi-directional trace reports instantly with just one click. Whether you're preparing for an audit or managing a recall, Wherefour compiles all your trace data into a downloadable Excel file—complete with lot history, quantities, dates, and users—so you can respond quickly and confidently, every time.

Track every ingredient and product in real time, from sourcing to shipping. Wherefour gives you full visibility to reduce waste, improve planning, and meet FSMA 204 traceability requirements without extra effort.

Access your traceability data from anywhere—desktop, tablet, or mobile. Wherefour keeps records secure, updated in real time, and always ready when your team needs them, whether onsite or working remotely.

Instantly pull traceability records by lot, ingredient, or date. Whether you're responding to a recall or audit, Wherefour gives you the speed and accuracy to act confidently and prove compliance quickly.

Transfer inventory between locations with just a few clicks. Each movement is logged by user, time, and lot, making it ideal for multi-facility teams and businesses with bonded or regulated storage.

Print custom barcodes with expiration dates, batch info, and locations. Scan materials at every stage for accurate traceability—from raw ingredients to finished goods—without guesswork or disconnected data.

Wherefour is designed specifically for food production. Manage allergens, maintain regulatory compliance, and ensure lot-level traceability in a single system. No spreadsheets, no silos, no workarounds required.

Staying ahead of food safety rules doesn’t have to slow you down.

Wherefour makes compliance simple with real-time traceability, automated lot tracking, and paperless records linked to every transaction. Attach COAs, track allergens, and generate audit-ready reports, all without digging through binders or spreadsheets.

Wherefour continues to upgrade and add options! Their support staff is great and responsive to support tickets. This program runs our entire manufacturing operation and we have had little to no problems. The company listens to the needs of their customers and prioritizes upgrades and features based on immediate customer needs. This is outstanding, and basically unheard of in the industry.

Our favorite aspects of Wherefour are the ease of Production planning, tracking, and inventory recording. We are a certified organic organization and having access to all of our records in one place makes our audit periods so easy. Wherefour is truly built out for traceability and it does not fail!

WhereFour is a great traceability tool with solid capabilities for inventory, recipe management, and cost control. The UI uses modern web tools which makes it easier to use than other older platforms. The technology base also is built on tools that will allow scalability and easier integration with other platforms.

Wherefour is very user friendly, and well suited to our food manufacturing business. We use this across multiple departments daily. The customer support is second-to-none, and from implementation to process integration to product launch we were well taken care of at every step!

Track every ingredient, package, and finished product, from sourcing to delivery, all in one system. Wherefour gives you true farm-to-table traceability with real-time visibility across your entire supply chain.

Need to track which supplier delivered a specific lot of basil? Done. Want to see which customer received a product containing sesame? Just a few clicks.

Attach COAs, monitor allergens automatically, and generate lot-level reports instantly. When an auditor drops by or a recall hits, you won’t be scrambling through spreadsheets—you’ll already have the answers. With Wherefour, complete traceability isn’t just possible, it’s built into everything you do.

Use our calendar to schedule a call with one of our experts to learn how Wherefour can help you take your food traceability efforts to the next level.

© 2024 Wherefour, Inc. - All rights reserved.