Wherefour saves distributors up to 25% on labor and inventory costs.

Get a demo

Product distributors need to scale activities according to demand and often expand product lines or provide customized options.

Traditional manufacturing ERPs can often be locked into requiring a rigid bill of materials and offer limited flexibility for adjusting formulas or production batches on the fly to meet fluctuating demand.

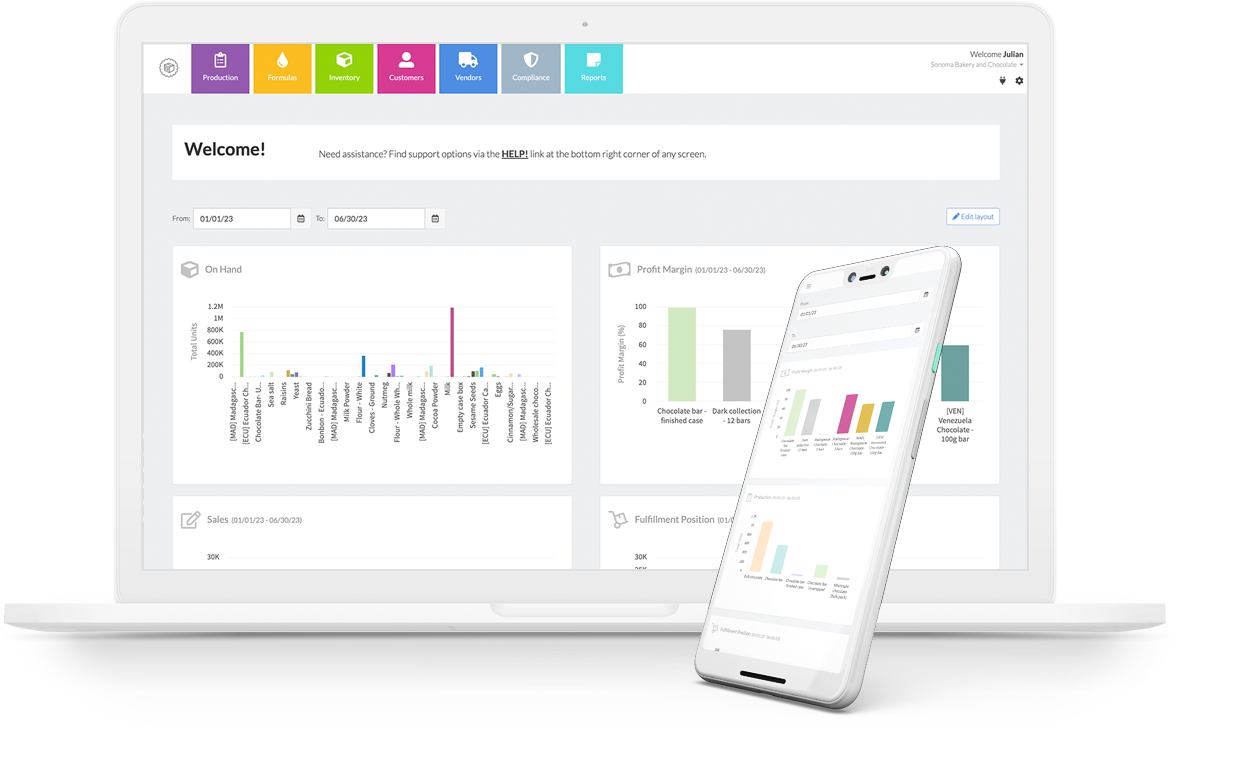

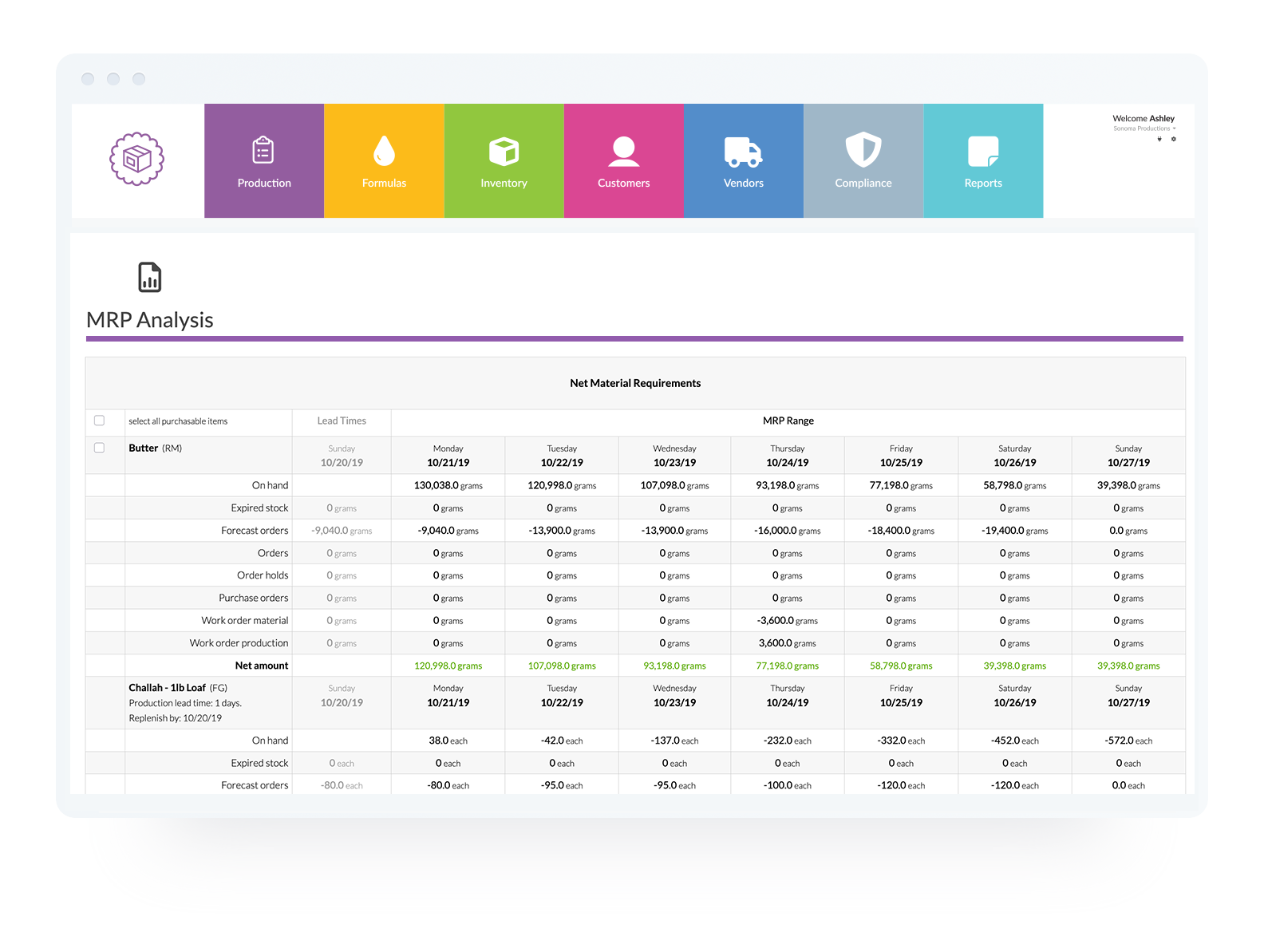

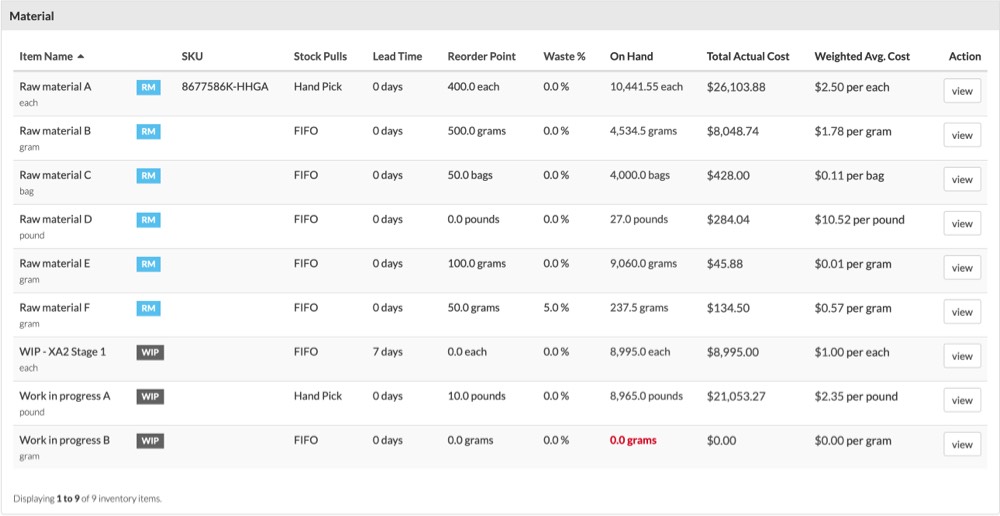

The global nature of product distribution requires careful inventory planning and control of lead times. Wherefour's modern inventory forecasting, "what if" and MRP functions are purpose-built to help distributors accurately and easily forecast, plan and execute inventory purchasing to maximize the availability of materials while minimizing the amount of cash tied up in inventory. Wherefour's modern inventory forecasting, "what if" and MRP functions are purpose-built to help manufacturers accurately and easily forecast, plan and execute inventory purchasing to maximize the availability of materials while minimizing the amount of cash tied up in inventory.

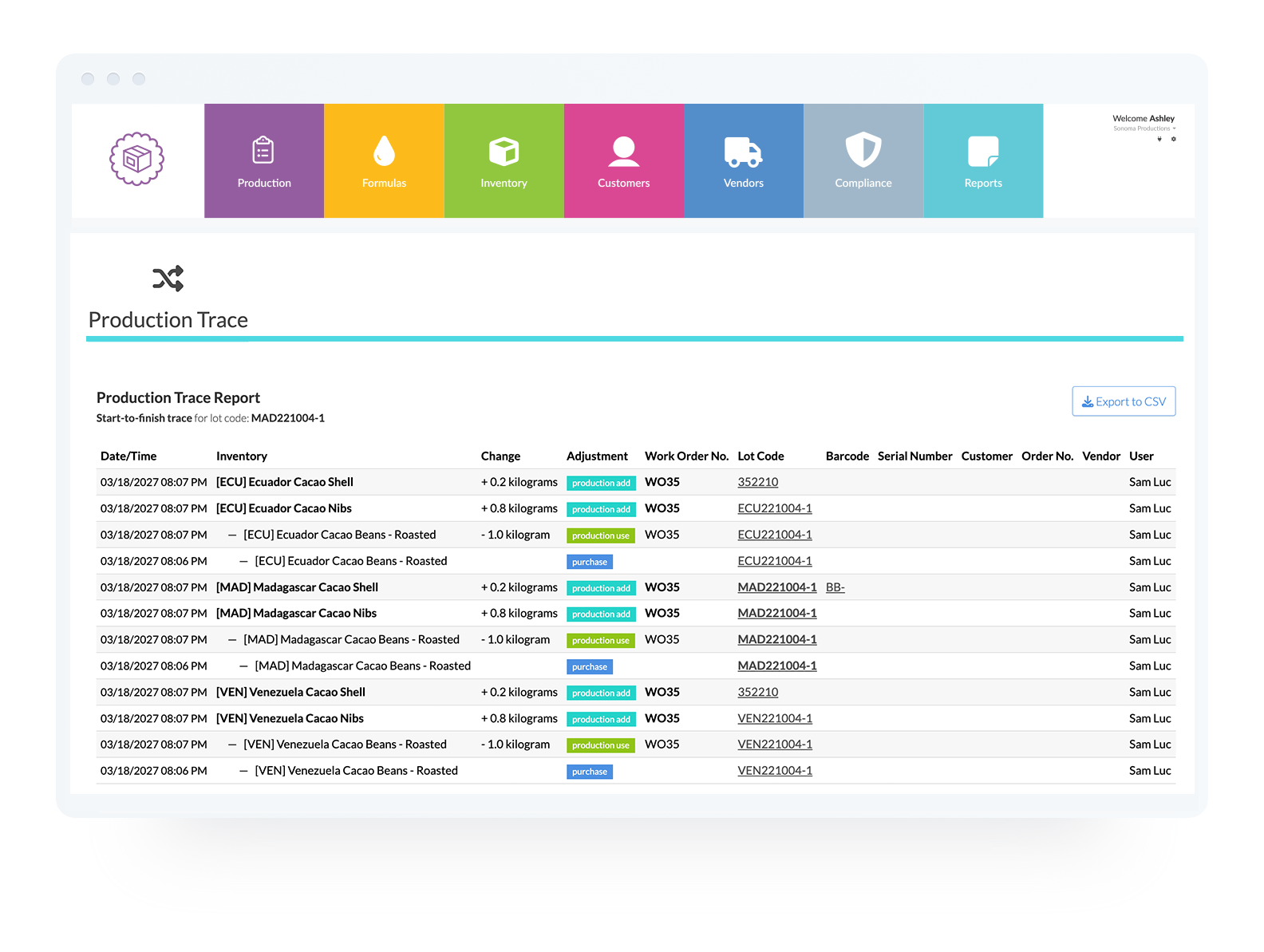

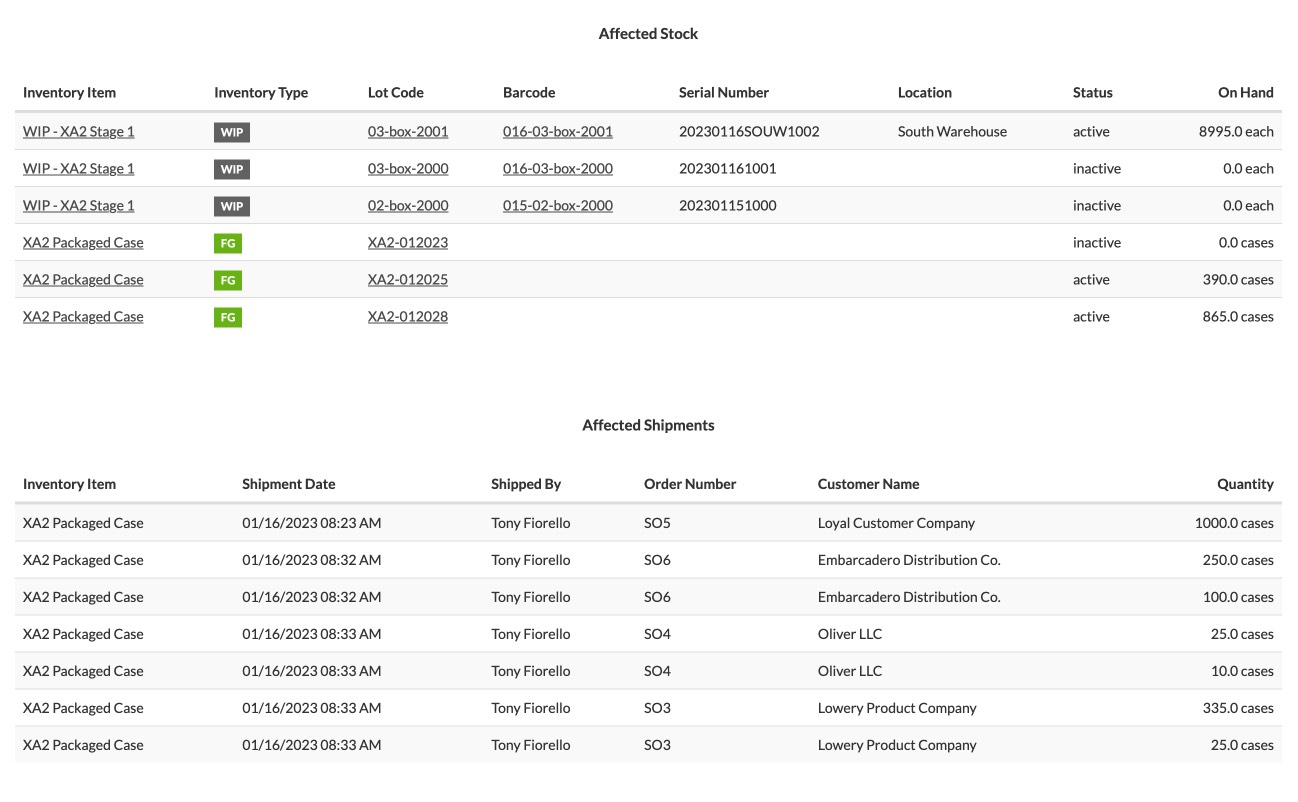

Wherefour's distribution software module can partially fulfill customer orders, or a series of standing orders from key customers, and maintain full traceability of what went where and when. Our platform supports and maintains your requirements for inventory control, quality, costing, lot traceability, compliance, planning, scheduling, and warehousing or distribution of products.

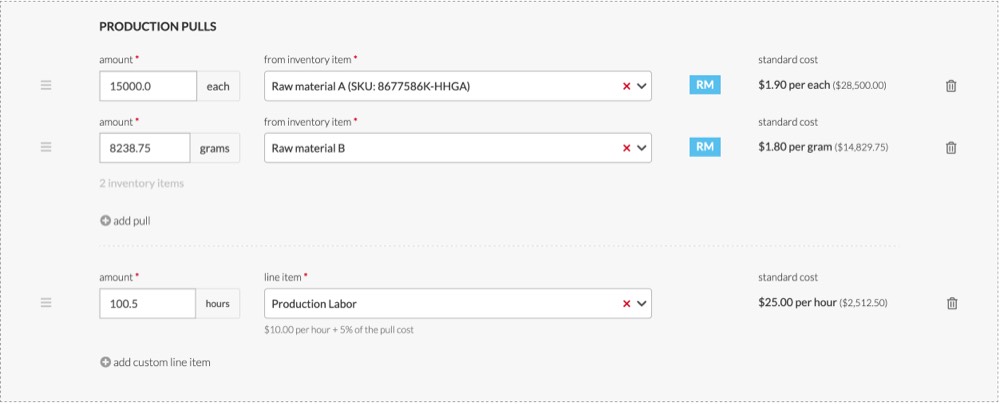

Design a custom workflow for product assembly or packaging that matches the process you are already doing. Overhead, like labor or unexpected costs for a specific assembly, can also be added and included in COGS automatically.

Unlike many traditional ERPs, Wherefour's platform lets you create variable results from each process, or even run a disassembly process where something is purchased and broken into new material that is then used in other products.

Determine what material you need now and in the future quickly and easily, while factoring lead times, reorder points and all the activity in your business. Create new purchase orders for replenishing inventory with a single button click!

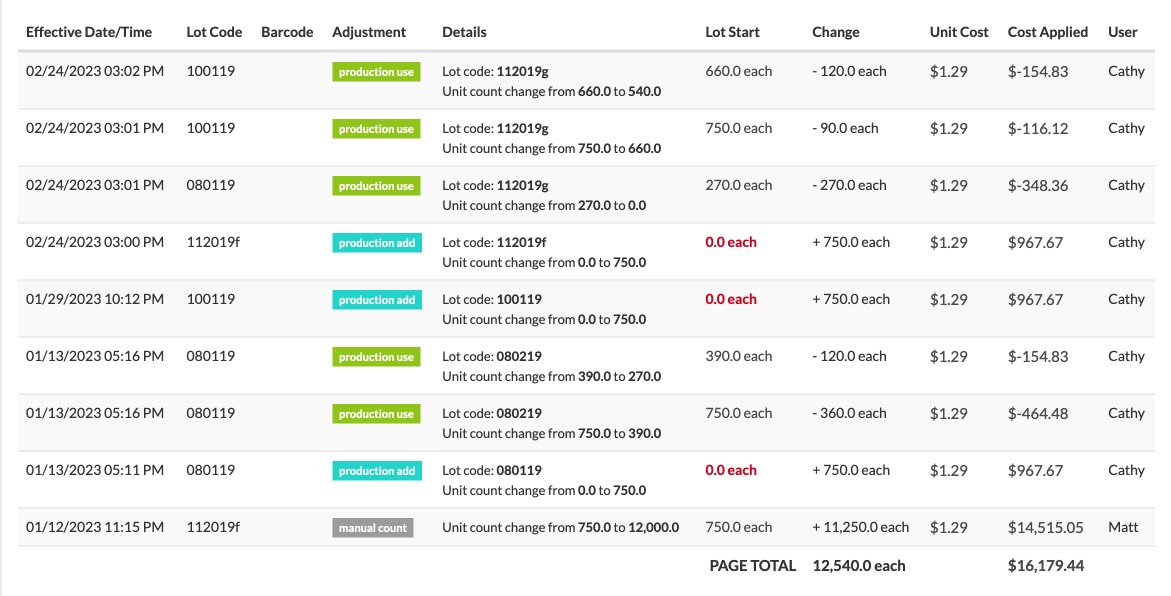

Track everything used in your product business, including the user who did the transaction, the date and time, and all the associated costs as well. A button click generates full traceability reports showing material still in your facility and what went to customers.

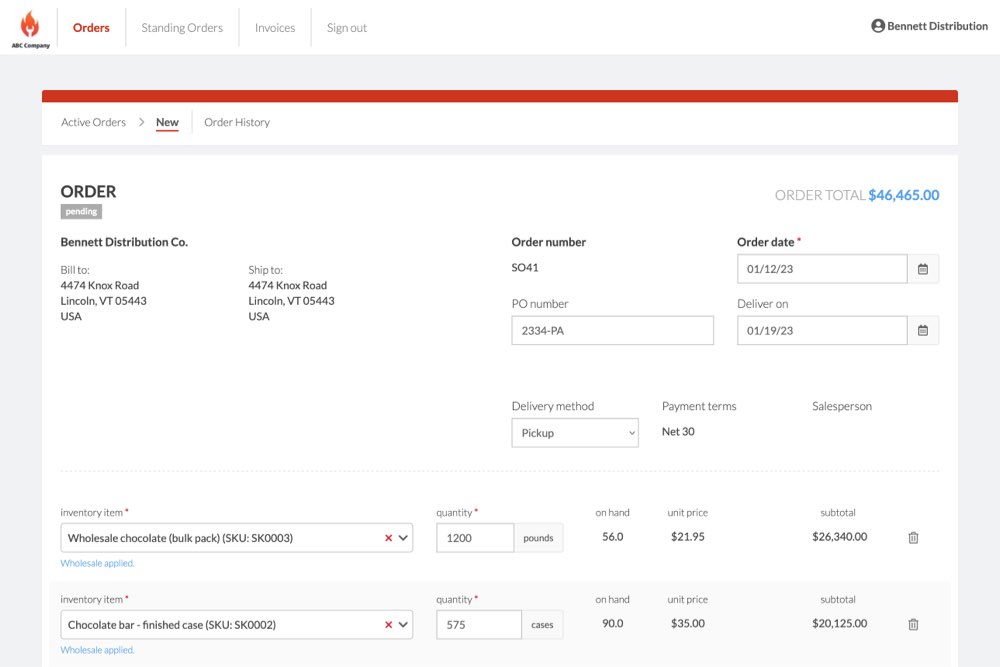

Our customizable B2B ordering portal lets you give customers access to their own orders, standing orders and invoice history. You control what products they can order and what prices they pay. Wherefour can even apply promotional pricing based on the time of year or purchase volumes.

Whether you sell products through ecommerce, put them into distribution, or a combination of both, Wherefour's integrations and workflow help you automate the more time-consuming aspects of your business, such as order entry and fulfillment.

Wherefour’s work order-driven production module makes it easy to customize your workflow to what meets your needs. From consistent, daily production to production needs that are driven by your daily customer orders, we’ve got you covered. COGS tracking means that your true production costs are just a click away.

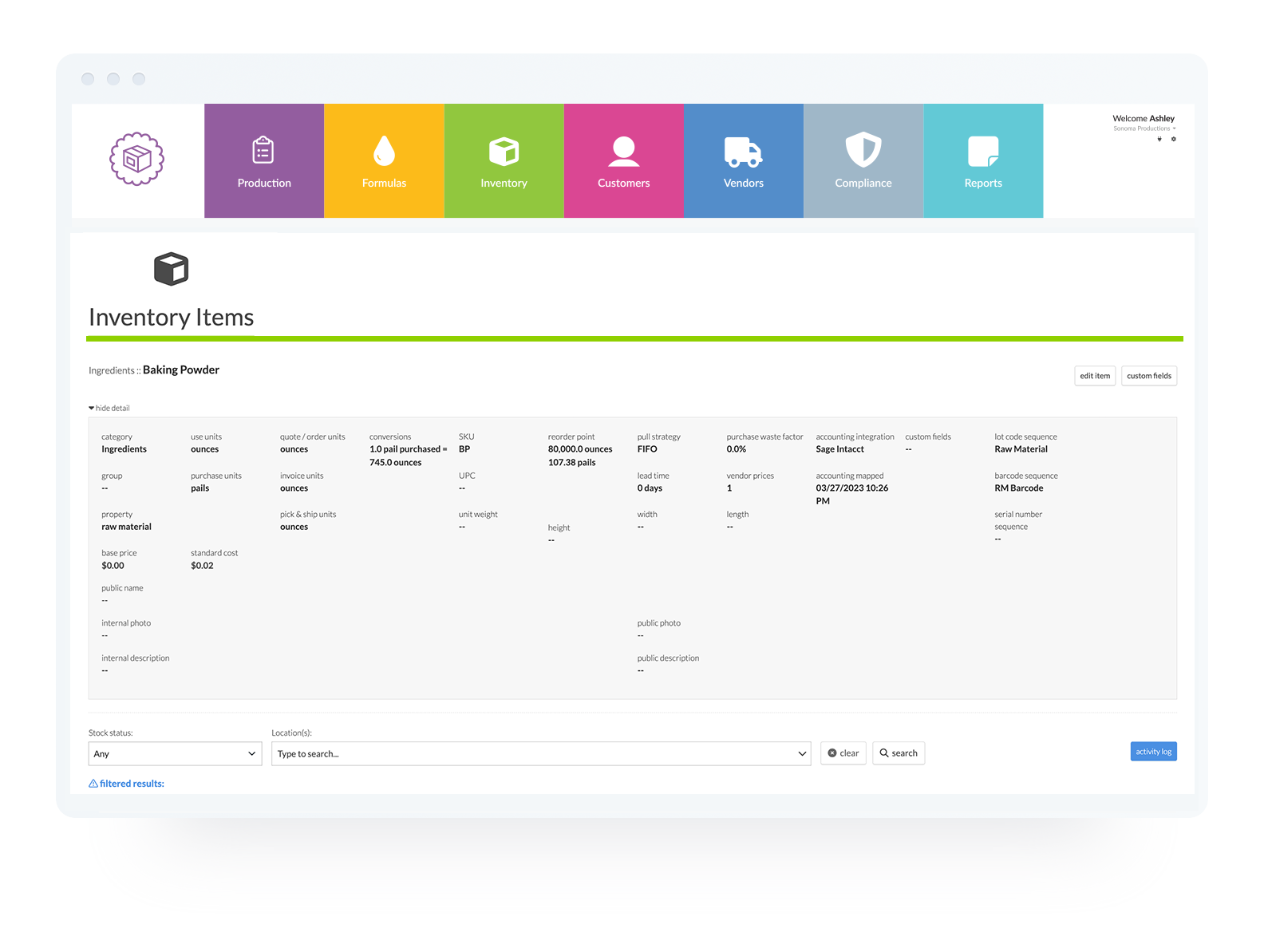

With Wherefour’s inventory and lot tracking capabilities on the job, drill into any item in inventory to see on hand amounts, status, cost and traceability aspects. Pull inventory for production based on FIFO, FEFO, LIFO or user-selected lots and transfer inventory between locations with a couple of clicks. Wherefour will send you automatic reorder, wastage and expiration notices. And yes, we can handle catch weights!

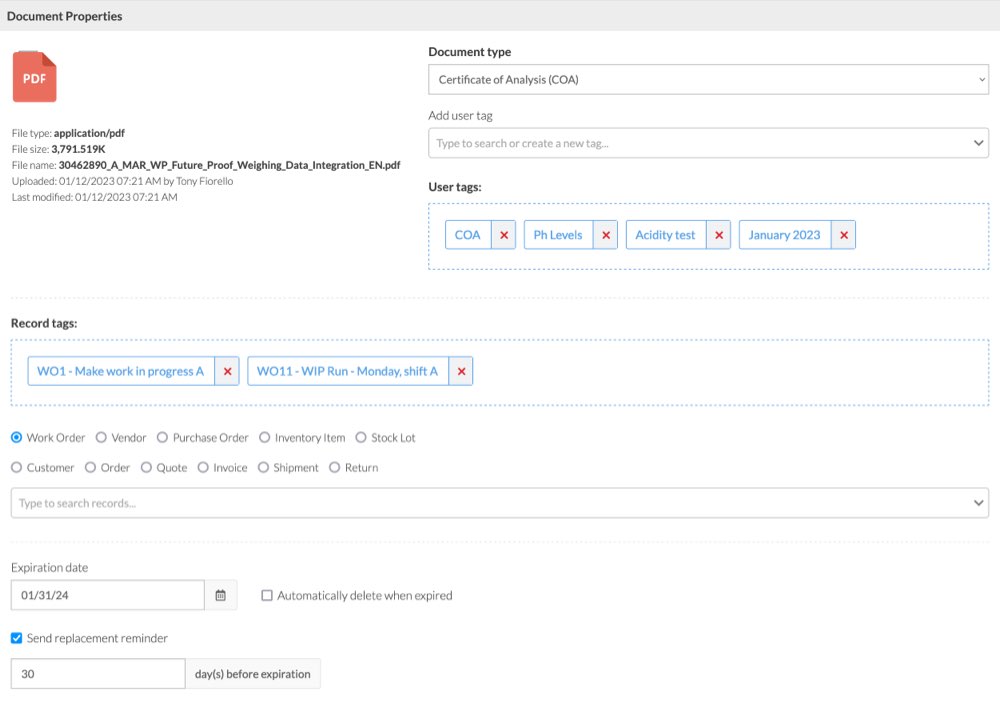

Keep inventory, production and compliance data in one place, accessible 24/7 from anywhere in the world. Upload, store and “tag” an unlimited number of compliance documents, such as COAs, lab test results, photos, scanned notes, PDF files, spreadsheets and more. If you’re using a mobile device, use the camera to snap an instant record and store it with the rest of your data.

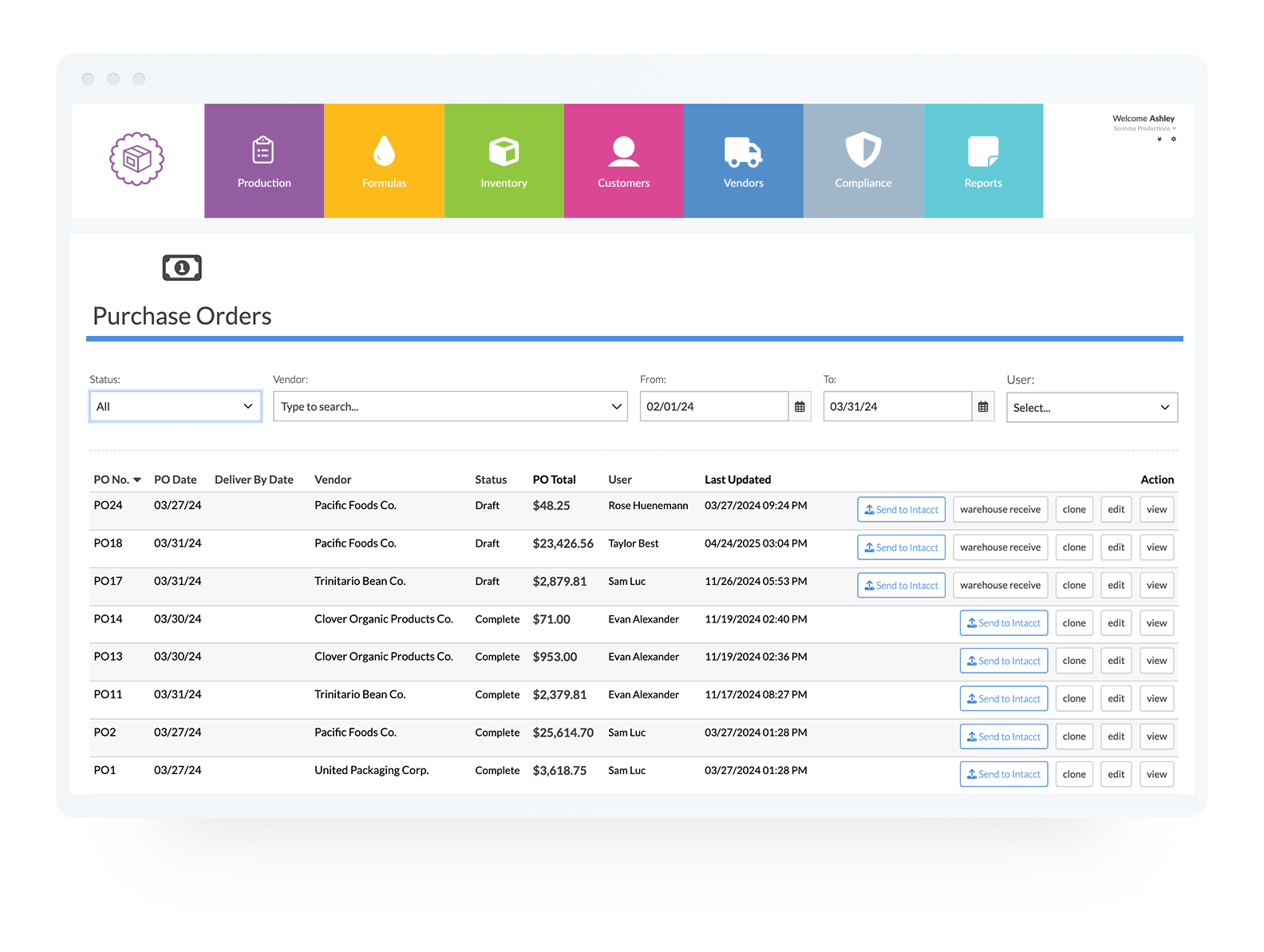

Track the suppliers and true cost of each purchase as it is checked into inventory. Wherefour will send you automatic email alerts when inventory items are below your reorder thresholds or is about to expire. We'll even create POs automatically for your preferred suppliers.

Custom (and automatic) lot code, barcode or serial number sequences that incorporate batch date, expiration date, julian date, facility, location, etc.

Automatically pull ingredients and supplies via FIFO, FEFO, LIFO or on a per-batch need.

Print GS1, Code 128 or Code 93 barcodes for product, inventory, package or pallet labels.

Automatic alerts for expiring products or ingredients reaching low levels.

Manage and organize your formulas and production instructions, including base products and variants.

Manage and organize your formulas and production instructions, including base products and variants. Add overhead such as labor time or equipment rental costs to specific formulas, or just to specific production batches.

Add overhead such as labor time or equipment rental costs to specific formulas, or just to specific production batches. Maintain and track standard cost and yield variances.

Maintain and track standard cost and yield variances. Purchase ingredients and supplies in bulk, in different units of measurement and convert them to your recipe units.

Purchase ingredients and supplies in bulk, in different units of measurement and convert them to your recipe units.

Run instant reports showing the inventory movements or changes made by each user.

Run instant reports showing the inventory movements or changes made by each user. Automatically show shipped lot code detail on customer orders and invoices.

Automatically show shipped lot code detail on customer orders and invoices. Instant forwards/backwards or bi-directional trace reports.

Instant forwards/backwards or bi-directional trace reports.

Recall and production trace reports show which customers got which products (with lot codes!) with one-click.

Recall and production trace reports show which customers got which products (with lot codes!) with one-click. Upload and maintain COAs, bills of lading, photos of deliveries, or other compliance paperwork digitally in one system with searchable tags for easy recall when needed.

Upload and maintain COAs, bills of lading, photos of deliveries, or other compliance paperwork digitally in one system with searchable tags for easy recall when needed. Design custom QA tests and attach results to stock lots or production runs.

Design custom QA tests and attach results to stock lots or production runs.

Directly integrate with QuickBooks® Online, QuickBooks® Desktop, Sage Intacct, Microsoft Dynamics or Xero.

Directly integrate with QuickBooks® Online, QuickBooks® Desktop, Sage Intacct, Microsoft Dynamics or Xero. Sync customer/vendor records with your accounting system.

Sync customer/vendor records with your accounting system. Export invoices and POs to your accounting system.

Export invoices and POs to your accounting system. Easily create journal entries for COGS, COGM, or inventory purchasing and usage.

Easily create journal entries for COGS, COGM, or inventory purchasing and usage.Wherefour continues to upgrade and add options! Their support staff is great and responsive to support tickets. This program runs our entire manufacturing operation and we have had little to no problems. The company listens to the needs of their customers and prioritizes upgrades and features based on immediate customer needs. This is outstanding, and basically unheard of in the industry.

Our favorite aspects of Wherefour are the ease of Production planning, tracking, and inventory recording. We are a certified organic organization and having access to all of our records in one place makes our audit periods so easy. Wherefour is truly built out for traceability and it does not fail!

WhereFour is a great traceability tool with solid capabilities for inventory, recipe management, and cost control. The UI uses modern web tools which makes it easier to use than other older platforms. The technology base also is built on tools that will allow scalability and easier integration with other platforms.

Wherefour is very user friendly, and well suited to our food manufacturing business. We use this across multiple departments daily. The customer support is second-to-none, and from implementation to process integration to product launch we were well taken care of at every step!