Food recalls, safety regulations, and consumer demand for transparency have made traceability a top priority in the food industry. The best food traceability software helps businesses stay ahead by tracking every product's journey, from raw ingredients to final delivery.

These platforms enable businesses to manage recalls, meet compliance standards, and minimize waste by providing real-time visibility into every stage of the supply chain. Choosing the right system can transform how your team handles traceability and quality control.

In this article, we’ll cover everything you need to know about the best food traceability software, including key features, top platforms, and how to choose the right solution for your business.

What is Food Traceability Software?

Food traceability software tracks and records the movement of food products across the entire supply chain. It captures essential data at every stage: where ingredients come from, how products are processed, when they’re shipped, and how they’re stored. This enables companies to trace every item with confidence and precision.

Using tools like barcodes and RFID tags, the software enables real-time monitoring and instant access to detailed product histories. Teams can quickly identify issues, locate affected batches, and take swift action during product recalls.

Food traceability software helps businesses reduce waste, prevent expired or damaged goods from reaching consumers, and strengthen trust in their brand. It’s an essential tool for any company committed to safety, transparency, and compliance.

Upstream vs. Downstream Tracing

Food supply chain traceability can be categorized into two key areas: upstream and downstream tracing.

Upstream tracing focuses on the origin of your ingredients and raw materials. It tracks the entire journey before production, capturing details like which suppliers were involved, what materials were used, and how those inputs were handled or processed. This gives companies a complete historical record of every component that goes into their products.

Downstream tracing kicks in once products leave the production facility. It follows the movement of goods through distribution and delivery, all the way to the end customer. This includes tracking carriers, transport routes, storage conditions, batch numbers, shipping dates, and the warehouse that fulfilled the order. It’s essential for identifying exactly where a product went and who received it.

The Importance of Food Traceability in Supply Chains

Food traceability enables rapid identification of safety issues, helping businesses isolate problems and take corrective action before they escalate. In a recall scenario, every second counts, and traceability delivers the speed and clarity needed to respond effectively.

These systems also serve as real-time quality control checkpoints. They confirm product authenticity, ensure proper handling throughout the supply chain, and verify goods meet required safety and labeling standards. With accurate traceability in place, companies gain the confidence to stand behind every product that reaches their customers.

Beyond safety, traceability offers significant operational benefits. It:

Simplifies compliance with evolving food regulations

Streamlines internal and external audits

Supports certification processes, such as organic or GMO-free labeling

Traceability provides the proof behind your promises so you can back your marketing claims with transparent, verifiable data.

Today’s consumers expect visibility into what they buy. Food traceability delivers that by allowing brands to share where ingredients come from, how products were processed or manufactured, and when and how they were shipped. The trust built with this level of transparency gives businesses a competitive edge in an increasingly regulated and accountability-driven market.

Best Food Traceability Software

Food traceability software helps you track ingredients, monitor production, and respond quickly to safety issues or recalls. Here are the best food traceability software solutions to XXX:

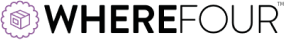

1. Wherefour

Wherefour is a modern food and beverage ERP platform built with traceability at its core. Designed specifically for manufacturers and producers, it offers complete visibility across your supply chain. It tracks raw materials, production batches, and finished goods with precision and ease. Whether you're preparing for an audit, running a mock recall, or managing day-to-day inventory, Wherefour provides the tools to keep you fully compliant and always ready.

Unlike traditional systems that treat traceability as an add-on, Wherefour bakes it into every workflow. Users can generate full forward, backward, or full recall reports in seconds, filter by lot, date, or customer, and access complete audit trails at any time, even from a mobile device.

Best for: Food and beverage manufacturers seeking built-in traceability, audit readiness, and inventory control in a single ERP platform

Features:

Automate lot code tracking: Automatically generate and apply lot codes across raw materials, production, and deliveries.

Monitor production from start to finish: Get full visibility into every stage, from ingredient sourcing to final shipment.

Generate instant recall reports: Create forward, backward, or full recall reports in seconds, organized by lot number, customer, or date.

Forecast inventory needs accurately: Use real-time inventory data and built-in MRP tools to plan purchasing and production with confidence.

Maintain compliance with ease: Attach COAs, track allergens, and log every transaction for fast, audit-ready reporting.

Access the platform anywhere: Use Wherefour from any device, desktop, tablet, or mobile, for full operational control on the go.

Integrate with 5,000+ platforms: Sync seamlessly with tools like QuickBooks, Xero, and ecommerce platforms to streamline your workflows.

Pros:

User-friendly and availability of necessary modules.

Ease of production planning, tracking, and inventory recording.

Amazing customer service team.

Cons:

Initial setup and onboarding can take time, but is made seamless by the customer support team.

Pricing: Wherefour provides custom price quotes depending on your company’s specific needs.

Schedule a free demo with Wherefour today.

2. SafetyCulture

SafetyCulture enables users to conduct inspections, capture operational data, and document each step of the production and supply chain. The platform enables teams to create custom workflows, assign tasks, and document information using checklists, photos, and videos. It facilitates cross-team communication and offers a centralized system for monitoring compliance, identifying issues, and tracking accountability.

Best for: Operational monitoring across multiple frontline teams

Features:

Inspection and audit tools: Conduct routine checks on food handling, preparation, and storage to meet internal standards.

Workflow builder: Create custom workflows to document and monitor traceability from production to distribution.

Multimedia documentation: Capture photos and videos to support compliance, traceability, and internal reporting.

Issue tracking and assignments: Identify traceability issues during inspections and assign follow-up actions to responsible teams.

Pros:

Allows users to comply with current safety regulations

Enables users to record inspections, take pictures, and videos.

Cons:

Requires continuous monitoring to ensure that hazards and risks are identified and addressed quickly and correctly.

Not built as a food-specific ERP system

Pricing:

Free

Premium: $29/month

Enterprise: Custom price

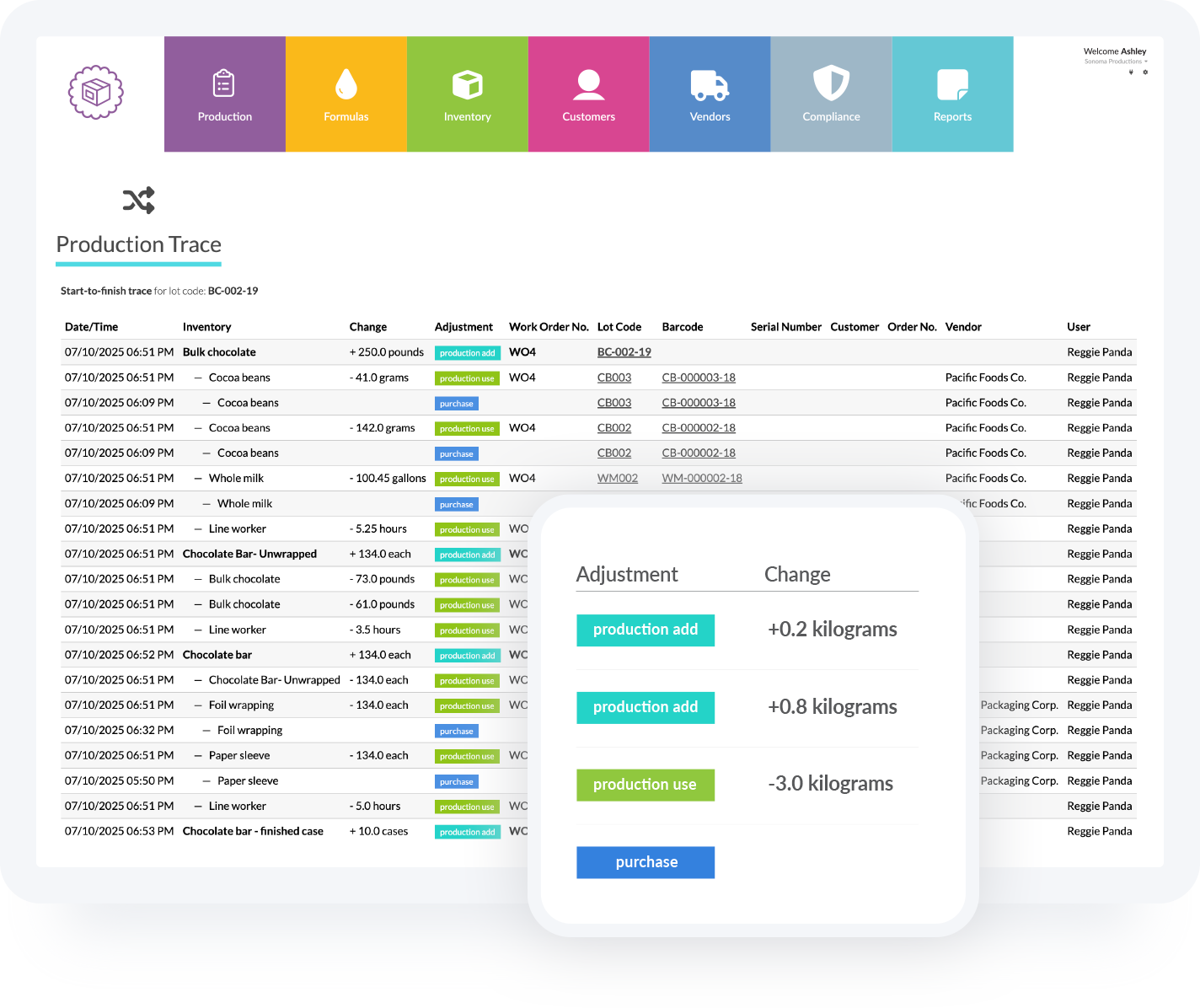

3. 3iVerify

3iVerify is a food safety and quality management system for manufacturers, retailers, and importers. It helps manage supplier information, corrective actions, food safety plans, and document control through one platform. The system replaces paper records and email-based tracking by bringing all tasks and records into one organized space.

Best for: Food manufacturers, retailers, and importers

Features:

Supplier management: Send reminders to suppliers, store certifications, and track approval status.

Corrective action tracking: Assign and follow up on actions from inspections, audits, or complaints.

Document control: Store and update safety procedures, policies, and checklists with access for all users.

Audit preparation tools: Generate reports and show compliance with food safety standards like BRCGS and ISO 22000.

Pros:

Supports compliance with multiple food safety certification standards.

Sends automatic reminders for certificate updates and expirations.

Cons:

Requires guidance for teams new to digital systems during setup

Offers a less modern interface compared to newer platforms

Pricing: Pricing isn’t publicly available on the website.

4. Normex

Normex is a food safety and compliance management platform designed for small to mid-sized food businesses. It offers tools for inventory tracking, supplier management, HACCP plan oversight, and audit preparation. The platform helps businesses manage documentation, monitor quality and safety tasks, and meet regulatory requirements with configurable workflows and centralized records.

Best for: Small to mid-sized food businesses

Features:

Supplier management: Monitor supplier compliance, store certifications, and send automated reminders.

Inventory tracking: Monitor stock levels and expiration dates to reduce waste and maintain accuracy.

Audit management: Record nonconformities, assign actions, and track resolution for internal and third-party audits.

Pros:

Supports compliance with multiple food safety certification standards.

Sends automatic reminders for certificate updates and expirations.

Cons:

Requires a minimum of two users for any pricing plan.

Restricts dedicated live agent access to platinum users.

Pricing: Pricing isn’t listed on its website.

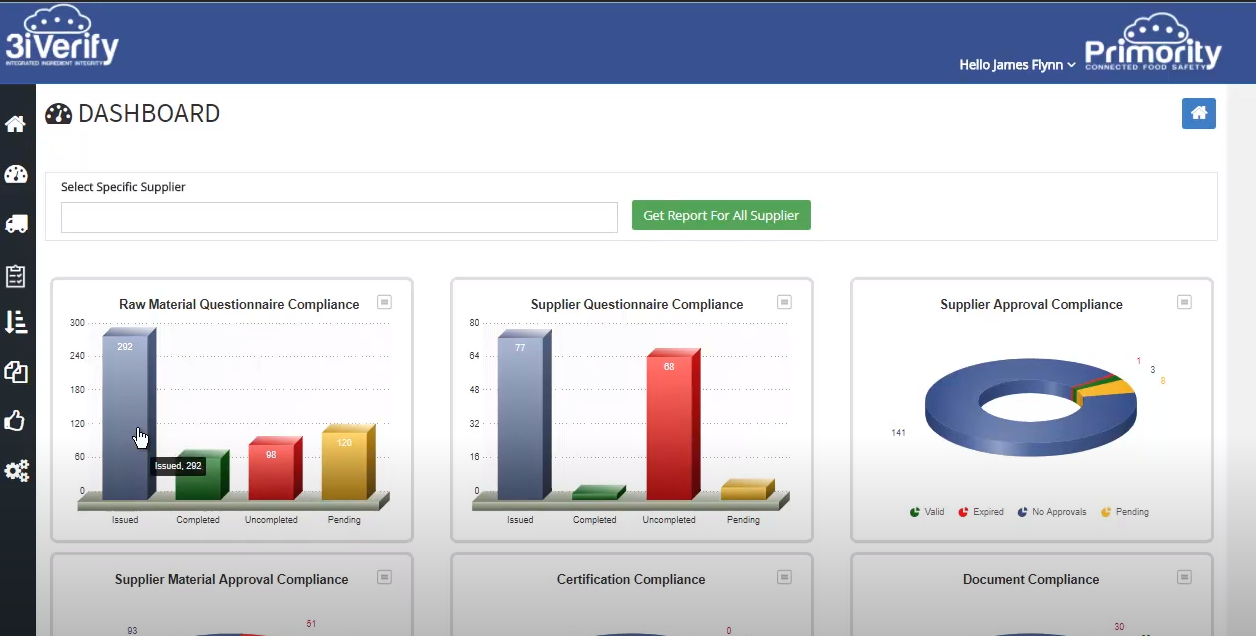

5. FoodDocs

FoodDocs is a food safety management system for hospitality, healthcare, and food production businesses. It helps teams meet food safety requirements through structured monitoring, task tracking, and traceability. Using a mobile app and dashboard, businesses can assign tasks, monitor compliance across multiple sites, and respond to potential food safety issues.

Best for: Multi-site restaurants, food manufacturers, care homes, and healthcare kitchens.

Features:

HACCP builder: Generates hazard analysis, SOPs, and flow charts based on company inputs.

Smart setup: Creates your food safety system based on a guided onboarding questionnaire.

Educative instructions: Adds photos or videos to tasks so staff complete them correctly.

Smart notifications: Sends mobile alerts to keep tasks on schedule.

Pros:

Provides supportive customer service.

Offers user-friendly SaaS and apps.

Cons:

Experiences occasional minor software glitches.

Restricts uploading of documents and files to multiple sites without technical support.

Pricing:

Basic: Free

Standard: $279/month

Professional: $409/month

Enterprise: Custom solution

6. Inspired Technology Systems

Inspired Technology Systems offers customizable ERP software designed for food manufacturers, cold storage operators, and distributors. It combines inventory tracking, food safety management, manufacturing, procurement, and billing into a single platform. The system can be deployed on-premise or in the cloud, allowing businesses to choose the setup that suits their infrastructure and scale.

Best for: Food manufacturers, distributors, and cold storage providers

Features:

Inventory management: Track raw materials, finished goods, and expiration dates across facilities.

Recipe and batch tracking: Manage ingredients, record yields, and schedule production by recipe.

Customer order tracking: Create sales orders, lock inventory, and monitor gross profit alerts.

Billing and AR management: Generate invoices, handle payment batches, and automate credit tracking.

Pros:

Provides modules for traceability, HACCP, and SQF compliance tailored to the food industry.

Supports both cloud-based and in-house deployment options.

Cons:

Offers limited information for the onboarding process and implementation timeline for new users.

Requires contacting sales for pricing or setup information.

Pricing: Pricing isn’t listed on its website.

7. FoodReady

FoodReady is a food safety and traceability software platform that combines digital tools with consulting services. Built for manufacturers, processors, and food service operators, it supports compliance with government regulations and food safety standards like SQF, GFSI, BRC, and FSMA 204. The platform includes modules for inventory, traceability, HACCP planning, supplier management, and more, all accessible via desktop or mobile.

Best for: Food safety software and consulting

Features:

HACCP/PCP builder: Create and manage food safety plans using templates and a visual process flow editor.

Supplier document management: Request, store, and update supplier documentation with automated reminders.

Traceability and recall: Link lots to production, shipping, and sales for end-to-end traceability and recall readiness.

Inventory tracking: Monitor batch data, bill of materials, and costs from receiving to finished goods.

Pros:

Combines software and food safety consulting under one platform.

Supports compliance with USDA, FDA, FSMA 204, SQF, and GFSI.

Cons:

Interface and setup may take time to configure for end-to-end operations.

Pricing:

Restaurant / Grocery / Food Service: Get a quote

Manufacturer / Processor Compliance: Get a quote

Enterprise: Get a quote

8. VicinityFood

VicinityFood is an ERP software built specifically for food and beverage manufacturers. It supports formula-based production workflows with tools that account for process variations, ingredient substitutions, and flexible packaging requirements. It is designed to serve as a single system across departments and brings together inventory, safety, production, and finance under one platform.

Best for: Formula-based food manufacturers

Features:

Recipe management: Document and adjust real-world recipe changes, substitutions, and actual ingredient usage.

Batch production tracking: Log multi-stage production runs and capture outputs, intermediates, and by-products.

Integrated operations: Connect production, inventory, finance, and sales in one centralized ERP.

QuickBooks & Microsoft Dynamics integration: Sync financial data seamlessly with popular accounting platforms.

Pros:

Built to support batch manufacturing workflows with flexibility around inputs and outputs.

Tracks recipe-level data, not just bills of material.

Cons:

Requires training to fully leverage advanced manufacturing features.

Pricing: Pricing isn’t available on the website.

9. Safefood 360

Safefood 360 is purpose-built to help food manufacturers meet the demands of global food safety standards, including GFSI, BRCGS, SQF, FSSC, and FSMA. The software includes over 35 pre-set modules covering everything from HACCP and PCP planning to real-time monitoring, supplier management, document control, and automated audit readiness.

Best for: Enterprise-level food and beverage manufacturers

Features:

Automated alerts: Get instant alerts on nonconformances, overdue tasks, or out-of-spec results to drive quick response.

Task automation: Automate recurring schedules and task assignments to ensure timely compliance activity.

Paperless compliance: Run a completely paperless food safety and quality management system.

Automatic standards updates: Stay up-to-date with global regulatory changes and food safety alerts, automatically synced in the system.

Pros:

Covers all major GFSI standards and global regulations.

Offers over 35 pre-built modules for end-to-end compliance.

Cons:

Tailors functionalities more toward enterprise companies.

Requires extra training to fully onboard and understand the scope of the software.

Pricing: Pricing isn’t available on its website.

10. Trustwell

Trustwell is a unified compliance and food safety platform. The platform provides tools for product formulation, regulatory compliance, labeling, supplier management, traceability, recall management, and quality assurance. Trustwell allows businesses to navigate complex regulations, streamline supply chain workflows, and maintain audit readiness through a combination of AI-powered features and industry-specific consulting support.

Best for: Managing supplier relationships

Features:

Product formulation: Access a database of ingredients to build and analyze recipes and supplement blends.

Supplier compliance: Track documentation, manage onboarding, and monitor supplier performance with scorecards and audits.

Recall management: Identify affected products and notify stakeholders to act quickly during recalls.

Quality management: Capture and respond to incidents with tools purpose-built for food quality teams.

Pros:

Includes AI-powered tools for regulatory assistance.

Offers nutrition and supplement labeling for over 30 countries.

Cons:

Contains multiple tools and modules, which increases the learning curve of the platform.

Pricing: Pricing isn’t available on its website.

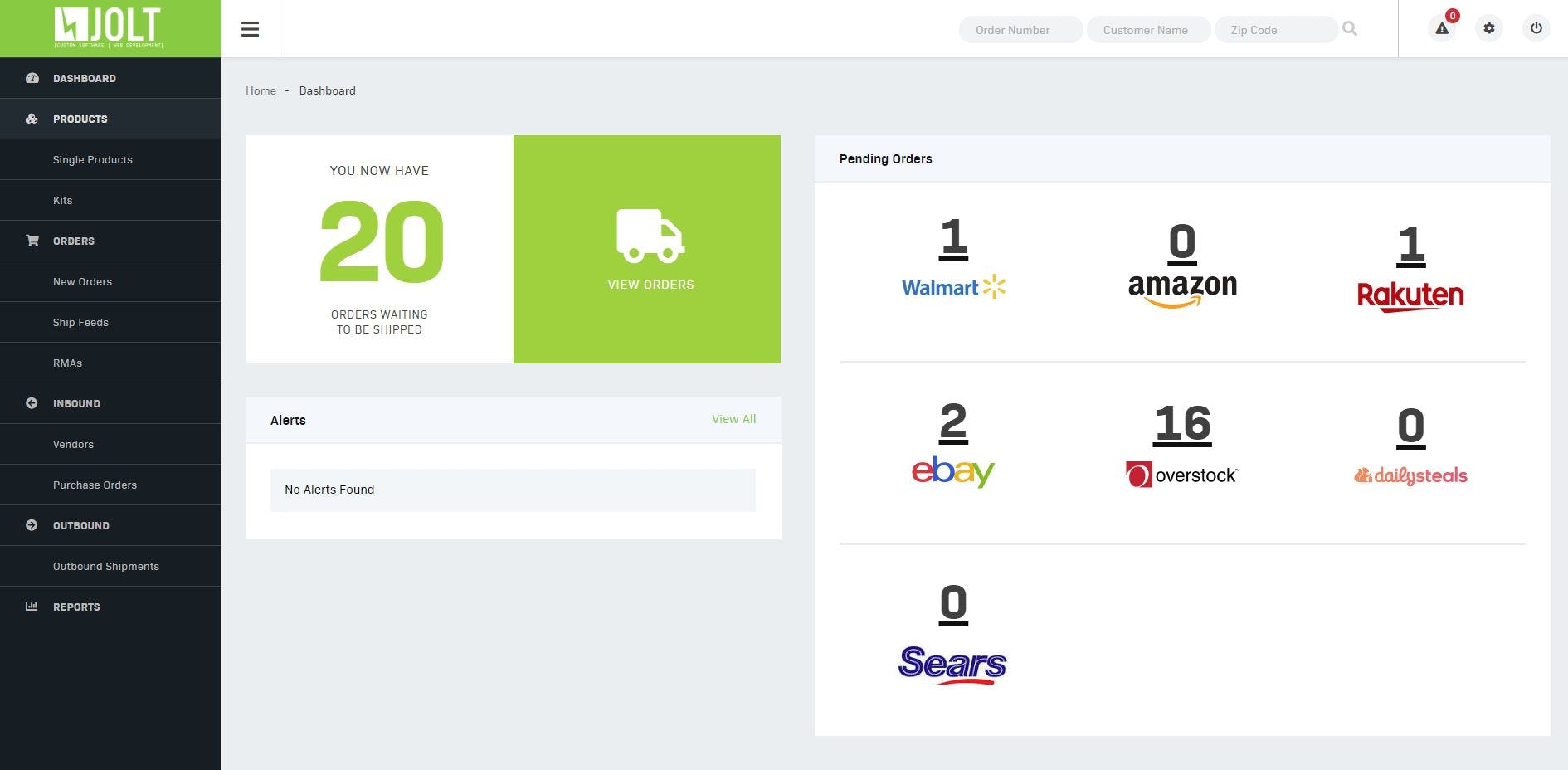

11. Jolt

Jolt is an operations management platform used across industries such as restaurants, retail, hospitality, and car washes. It provides digital tools for checklist completion, temperature monitoring, labeling, employee scheduling, time tracking, and team communication. The system includes hardware like probes and print stations, along with mobile access for remote task oversight.

Best for: Multi-location food businesses managing tasks, temperature, and staff

Features:

Task management: Manage tasks with custom digital checklists, QR scanning, photos, timestamps, and location verification.

Labeling system: Create centrally managed food labels for expiration dates, ingredients, to-go orders, and allergen alerts.

Temperature monitoring: Monitor temperatures with digital logs and alerts via sensors and temperature probes.

Work orders: Track work orders with custom forms for maintenance, safety, or operational issues, including real-time updates.

Pros:

Provides a user-friendly interface with a lot of additional features.

Enables users to monitor all restaurant locations daily, weekly, and monthly.

Cons:

Presents a high learning curve for new users.

Requires time and resources for the initial setup.

Pricing: Pricing isn't listed on its website.

What Are the Benefits of Using a Food Traceability Software?

Here are the benefits of using a food traceability software:

Meets safety standards: Food traceability systems help businesses meet regulatory requirements, including the FSMA (Food Safety Modernization Act), ISO 22000, and GFSI-recognized schemes such as SQF or BRCGS. These platforms support documentation, monitoring, and reporting tasks required to demonstrate food safety controls. With real-time records and built-in validations, they reduce the risk of falling short during inspections or third-party audits.

Maintains compliance: Traceability tools enable companies to consistently meet internal policies and external regulatory requirements by establishing structured workflows. Teams record activities in digital logs, schedule tasks, and set automated alerts to avoid missing or leaving anything undocumented. They retrieve these records instantly to confirm that protocols were followed, improving readiness for audits and reviews.

Ensures supply chain transparency: By collecting and linking data across suppliers, production sites, and distributors, the software creates a clear picture of the origin of each ingredient or product. It becomes easier to verify sourcing claims, track sustainability metrics, and monitor supplier performance. Transparency also fosters trust with partners and customers, who expect greater visibility into food origins.

Manages recalls: If a product issue arises, traceability software can help identify affected lots, suppliers, and customers within minutes. Automated reporting tools generate recall documentation quickly, while alerts guide internal teams through corrective actions. This reduces the cost and time of recalls while limiting the exposure to noncompliant or unsafe products.

Boosts productivity: Many manual tracking tasks, such as temperature logging, data entry, or certificate collection, can be automated. Employees spend less time on paperwork and more time on higher-value activities, such as quality checks or operational improvements. Built-in reminders and mobile tools also make it easier for staff to stay on task and meet compliance requirements.

Tracks food processes: From ingredient intake through processing to final delivery, food traceability platforms capture and connect data at every stage of the process. This visibility helps identify issues like bottlenecks, contamination risks, or inefficiencies in production. The ability to trace product paths backward and forward also supports root cause analysis and better decision-making.

The Role of Food Traceability Software in Ensuring Safety Compliance

Food traceability software plays a central role in meeting the growing regulatory demands placed on food businesses by providing a digital infrastructure to document and manage safety-related activities.

It enables companies to record ingredient sourcing, processing steps, temperature logs, and supplier credentials in one system, reducing the risk of undocumented processes or missing records. This level of control supports structured compliance with both government and third-party food safety standards, while also preparing businesses for unannounced inspections or audits.

Beyond documentation, traceability tools provide visibility across the supply chain to help identify potential safety risks before they impact consumers. Whether it's monitoring out-of-range temperatures, incomplete cleaning tasks, or supplier nonconformances, food traceability systems make it easier to detect and respond to these issues quickly.

How to Choose the Best Food Traceability Software for Your Company

When choosing the best food traceability software for your company, it’s important to consider how the software aligns with your operational needs, regulatory requirements, and future scalability. Here are key factors to look for when making your decision:

Choose software with an intuitive, user-friendly interface

Your team will use the software daily to complete tasks, monitor conditions, and document compliance. If the interface is confusing or difficult to navigate, it increases the risk of errors and reduces adoption across teams. Look for platforms that offer clear dashboards, mobile accessibility, and minimal training time to get staff up and running quickly.

Make seamless integration a must-have

Food safety doesn’t operate in isolation. Select software that integrates seamlessly with your existing tools, such as temperature sensors, labeling systems, supplier databases, or inventory management platforms. Integrated systems reduce data silos, eliminate duplicate entries, and facilitate the maintenance of a centralized record of compliance activities.

Opt for a solution that scales with your growth

As your business expands, you’ll need traceability software that can handle more locations, users, and product lines. A scalable solution should enable you to add new facilities, update processes, and onboard teams without requiring major overhauls or additional fees. This ensures long-term value and avoids costly system changes later.

Prioritize real-time, end-to-end data tracking

Traceability software should give you visibility from ingredient sourcing to final product delivery. Real-time data enables faster responses to missed tasks or supplier issues. This level of oversight is essential for both food safety and operational efficiency.

Demand robust, customizable reporting tools

Compliance audits require clear, accurate records. Choose software with reporting features that allow you to generate detailed logs, filter data by location or product, and export documentation as needed. Customizable reports also help identify recurring issues and support continuous improvement across your food safety system.

Discover the Best Food Traceability Software

Food manufacturers and processors face rising pressure to ensure product safety, maintain regulatory compliance, and respond rapidly to supply chain disruptions. In this environment, relying on manual logs, spreadsheets, or siloed systems can expose businesses to risk.

A modern food traceability solution provides real-time visibility across operations, tracking ingredients, monitoring temperatures, managing suppliers, and generating audit-ready reports with just a few clicks. With the right software, teams can automate data collection, minimize human error, and make informed decisions backed by accurate and accessible information.

Wherefour gives you complete visibility from raw materials through production and delivery. Whether you're reworking a batch or exporting audit data, Wherefour keeps a full digital trail, eliminating the stress of inspections and compliance events.

Ready to see how Wherefour can simplify your day-to-day?

Learn More About Food Traceability Software

What is RFID in food traceability?

RFID (Radio Frequency Identification) uses radio waves to transmit data from a tag attached to food products or containers to a reader device. This allows for non-contact, real-time tracking of inventory movement through the supply chain. In food traceability, RFID helps improve speed, accuracy, and automation in identifying and locating products across production, storage, and distribution.

What is the most effective food traceability system?

The most effective systems offer end-to-end traceability, allowing users to track ingredients and finished goods forward and backward through the supply chain. They include features like automated lot tracking, real-time data capture, supplier and recall management, and integration with other business systems. Effectiveness is also measured by the system's ability to generate audit-ready reports quickly and respond to compliance requirements without disrupting operations.

Is food traceability required by law?

Yes, in many countries, food traceability is a legal requirement, particularly for manufacturers, processors, and distributors. In the U.S., the FDA’s FSMA 204 rule outlines specific traceability recordkeeping mandates for certain high-risk foods. Similar regulations exist globally under frameworks like the EU General Food Law or Canada's Safe Food for Canadians Regulations.

How does food traceability software work?

Food traceability software tracks products from raw materials through production, packaging, distribution, and delivery by recording batch, lot, and transaction data at every stage. It centralizes this data, allowing users to search, generate reports, and initiate recalls based on specific parameters like dates, ingredients, or customers.

Most platforms automate data entry and integrate with other tools like labeling systems, temperature sensors, and ERPs for seamless oversight.

Does food traceability software support sustainability goals?

Yes, food traceability software helps reduce waste by improving inventory control and identifying inefficiencies across the supply chain. It supports better resource planning and can track sustainability metrics like sourcing origin, packaging usage, or energy-intensive processes. Transparent data also enables companies to validate environmental claims and meet consumer expectations around ethical sourcing and production.