Managing a food business today means more than producing great products. You also juggle compliance rules, ingredient traceability, and customer expectations, all while keeping costs under control. That’s why many food manufacturers look for better systems to handle the moving parts.

Traditional tools like spreadsheets can’t keep up with the demands of modern food production. You need a centralized platform that connects recipes, inventory, and quality control, so you don’t lose time or money when things get complicated.

This is where the best food ERP software steps in. In the sections below, you’ll discover leading platforms built for food and beverage manufacturing and learn how to choose the right one for your business.

What is Food ERP Software?

Food ERP software is a system designed specifically for food manufacturers. Unlike general ERP platforms, it includes tools that address the industry’s unique challenges, such as recipe management, compliance, and traceability.

These platforms connect every part of your business, from procurement and production to sales, inventory, and finance. With everything in one place, you can reduce waste, improve accuracy, and keep your supply chain transparent.

Key features often include batch and lot tracking, allergen and expiration monitoring, and regulatory compliance support. Together, these capabilities help food producers meet strict requirements while staying efficient and profitable.

Why You Need Specialized Food Manufacturing ERP Software

Food manufacturing comes with challenges that generic ERP platforms can’t solve. You need tools that manage compliance, trace ingredients, and connect production with sales in real time.

A specialized food ERP helps you:

● Stay audit-ready with compliance features that support Food Safety Modernization Act (FSMA), Hazard Analysis and Critical Control Point (HACCP), Safe Quality Food (SQF, and SOC 2 requirements)

● Maintain full product traceability for recalls, allergen control, and supplier tracking

● Streamline production with live barcode labeling, batch tracking, and automated workflows

● Connect sales channels like B2B portals and ecommerce sites to your inventory and fulfillment processes

● Improve planning with an enterprise-grade MRP that aligns purchasing, demand forecasting, and shelf-life management

By combining compliance, traceability, and operational efficiency, food ERP software gives manufacturers the control needed to grow while staying safe and profitable.

Best Food ERP Software Systems

Whether you manage a large-scale food operation or a small specialty kitchen, the right ERP system helps you stay efficient and compliant. Here’s the list of the best food ERP software systems built to keep compliance, operations, and profitability working in sync.

1. Wherefour

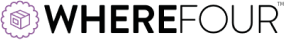

Wherefour is a cloud-based ERP built for food and beverage companies that need industry-specific tools, not generic workarounds. It centralizes purchasing, production, and forecasting, enabling teams to manage operations in one place while staying compliant with FSMA, HACCP, SQF, and SOC 2 standards.

The platform also supports traceability across every batch and ingredient, integrates with popular accounting and ecommerce tools, and offers mobile-friendly access for staff on or off the production floor. It’s designed to help food businesses cut waste, stay audit-ready, and keep operations running smoothly as they scale.

Features:

● Built-in recall reports tied to specific customers and lots

● Work order-driven production with true unit-level COGS tracking through accounting integrations

● Direct integrations with Shopify, ShipStation, LeafLink, and SPS Commerce

● User-friendly interface for shop floor and remote access from desktop, tablet, or phone

● Automatic lot, serial, or barcode sequencing with batch date, facility, or Julian date

● FIFO, FEFO, last-in, first-out (LIFO) inventory pulls for ingredients and supplies

● Start-to-finish traceability with real-time inventory visibility

● Custom QA test creation and linkage to specific stock lots or production runs

● Digital archiving of certificates of authenticity (COAs) and delivery images with searchable tags

● Global Standards 1 (GS1), Code 128, and Code 93 barcode generation for products

Pricing: Wherefour provides custom price quotes depending on your company’s specific needs.

Schedule a free demo with Wherefour today.

2. Aptean

Aptean is a cloud-native system built on Microsoft Dynamics 365 Business Central with built-in AI for assistance and forecasting. It addresses food industry needs like traceability, allergen control, catch weight, and regulatory requirements.

The platform unifies purchasing, production, inventory, quality, and finance. It supports bi-directional ingredient tracking, expiration controls with First-Expired-First-Out(FEFO), lot and origin management, and labeling for compliance needs.

Features:

● Built-in AI assistant and forecasting tools

● Bi-directional ingredient tracking and allergen management

● Expiration tracking plus FEFO inventory control

● Catch weight calculations tracked through to invoicing

● Lot tracing, item-level tracking, and product origin management

Pricing: No public pricing is available.

3. BatchMaster

BatchMaster is an ERP system that manages core processes such as formulation, production, inventory, and cost control with a formula-centric approach tailored to the food industry.

The platform also supports compliance with FDA, FSMA, USDA, and GFSI standards. With tools for nutritional labeling, allergen tracking, recall readiness, and electronic batch records, BatchMaster gives food producers control over both safety and production requirements.

Features:

● Recipe and formula management with yield/loss adjustments and nutrition profiling

● Batch processing with electronic batch records (EBR)

● Lot traceability and recall readiness with bi-directional tracking

● Shelf life and expiration date monitoring for perishable goods

Pricing: No public pricing is available.

4. DEAR Systems

DEAR Systems is a cloud ERP platform that combines inventory, production, sales, purchasing, and accounting in one system. Built for manufacturers, wholesalers, and retailers, it supports batch tracking, recipe management, warehouse control, and order fulfillment across multiple locations.

The software integrates with ecommerce, B2B portals, shipping carriers, and accounting tools like Xero and QuickBooks. Food manufacturers can capture all production costs, manage recipes through bills of materials, and maintain traceability for compliance and recalls.

Features:

● Batch and serial tracking for traceability and recalls

● Bills of materials (BOM) for recipe and cost management

● Multi-location inventory visibility with real-time updates

● Auto assembly and disassembly for kits and bulk purchases

● B2B portal for customer ordering and order management

Pricing:

- Monthly: ~$600

- Yearly: ~$10,000

5. Fishbowl

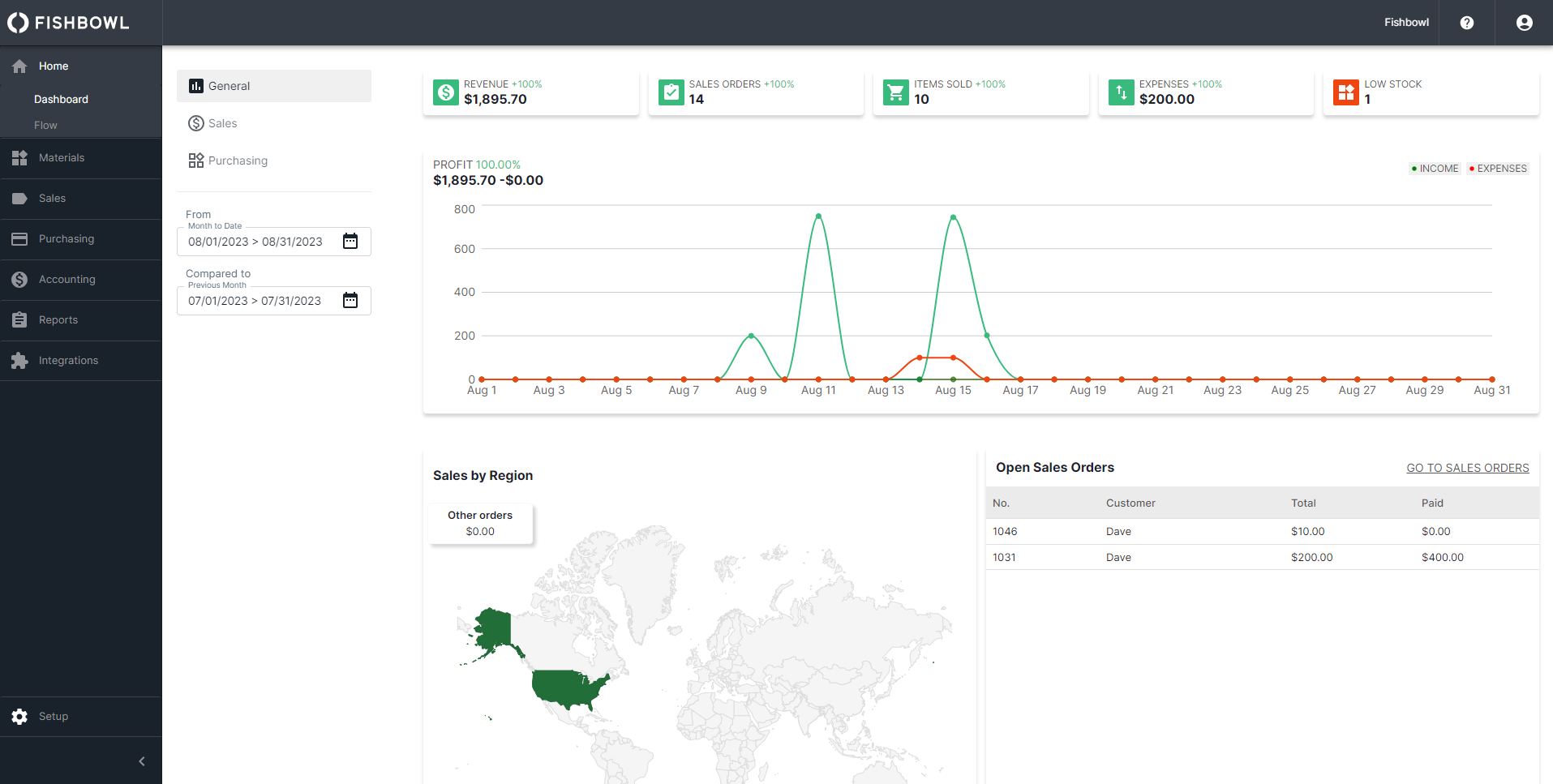

Fishbowl is an inventory management and manufacturing platform that supports food and beverage businesses in meeting strict compliance standards. It tracks ingredients, batches, and finished goods through production and distribution, giving manufacturers the ability to respond to audits and recalls with precision.

The system integrates inventory control, supplier management, and regulatory requirements into a single platform. It supports batch and lot tracking, expiration date monitoring, labeling, and permissions-based access.

Features:

● Batch and lot tracking for perishable goods

● Expiration date monitoring with FIFO support and custom alerts

● Role-based access permissions for staff and departments

● Supplier and vendor management with lead time forecasting

● Reporting options, including lot history, part activity, and sales/purchase summaries

Pricing:

- Essentials: $199/month

- Growth: $399/month

- Scale: $699/month

Advanced: Custom quote

6. Inecta

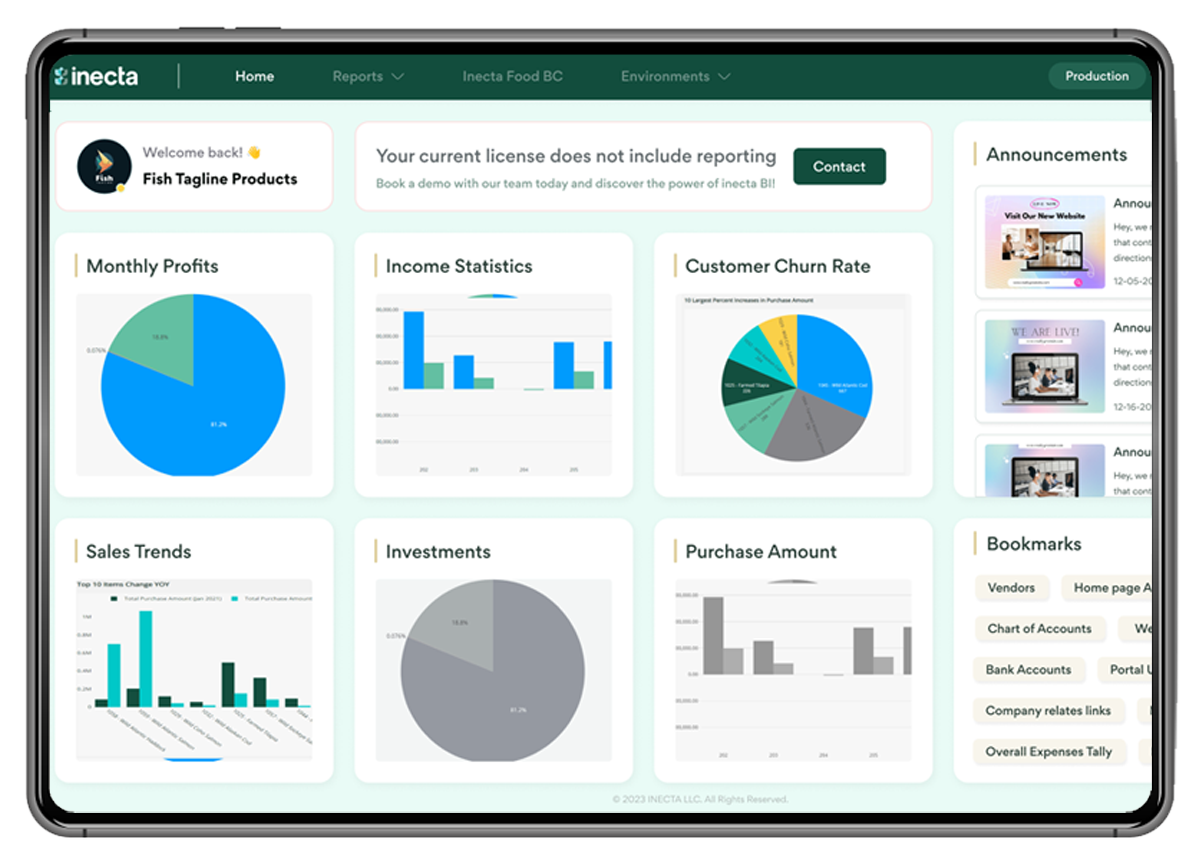

Inecta is a food-specific ERP powered by Microsoft Dynamics 365 Business Central. It serves manufacturers, processors, and distributors across sectors such as produce, seafood, meat, dairy, beverages, and packaged food. The system centralizes recipe management, production scheduling, supply chain tracking, and compliance functions in a single hub.

It supports industry requirements like FEFO inventory control, allergen tracking, and bidirectional lot traceability.

Features:

● Recipe and formula management with production scheduling

● Ingredient tracking for allergens and special diets

● FEFO inventory control and warehouse management

● Lot traceability with margin and cost analysis

● Compliance with FSMA and SQF standards

Pricing: No public pricing is available.

7. JustFood

JustFood is a cloud ERP designed for food manufacturers, processors, and distributors. It connects purchasing, production, inventory, sales, quality, and finance in a single system built on Microsoft Dynamics.

The platform adds food-specific functionality on top of standard ERP features, including recipe management, food safety tracking, recall readiness, and regulatory compliance. It provides integrated workflows so teams can align production, R&D, quality control, and distribution within one environment.

Features:

● Traceability tools for recalls and compliance with global standards

● Warehouse management for inventory movement and control

● Production scheduling with batch management

● Recipe development and product R&D support

● Reporting and analytics with real-time and historical data

Pricing: No public pricing is available.

8. Katana

Katana is a cloud ERP that consolidates sales, purchasing, inventory, production, and accounting in one system, with real-time visibility across multiple channels and warehouses.

The platform connects directly with ecommerce, accounting, and shipping tools, allowing companies to manage recipes, track batches, plan demand, and oversee production workflows from a single hub. Katana supports both make-to-stock and make-to-order processes, giving manufacturers control over raw materials and finished goods.

Features:

● Inventory management with reorder points, traceability, and multi-location support

● Purchase management with order tracking, multicurrency, and supplier insights

● Sales order management with multichannel support, partial shipping, and invoicing

● Planning and forecasting tools for demand and replenishment

● Warehouse management with barcode scanning, bin locations, and mobile workflows

Pricing:

- Starter plan: From $199/month

- Standard: From $399/month

- Professional: From $899/month

- Add-ons (e.g., warehouse, batch tracking, API access): $199/month or more each

9. Plex

Plex, a Rockwell Automation company, combines enterprise resource planning with manufacturing execution to provide oversight from the shop floor to the top floor.

The system emphasizes traceability, compliance, and risk management while centralizing data on production, supply chain, and quality. Powered by Industrial IoT (IIoT) and real-time analytics, Plex helps manufacturers connect processes, monitor performance, and prepare for audits or recalls.

Features:

● ERP and MES integration for production lifecycle management

● Financial management, accounting, and enterprise consolidation

● Supplier and purchasing management with RFQs, purchase orders, and requisitions

● Lot traceability and recall management

● Human capital management for labor, skills, and training tracking

Pricing: No public pricing is available.

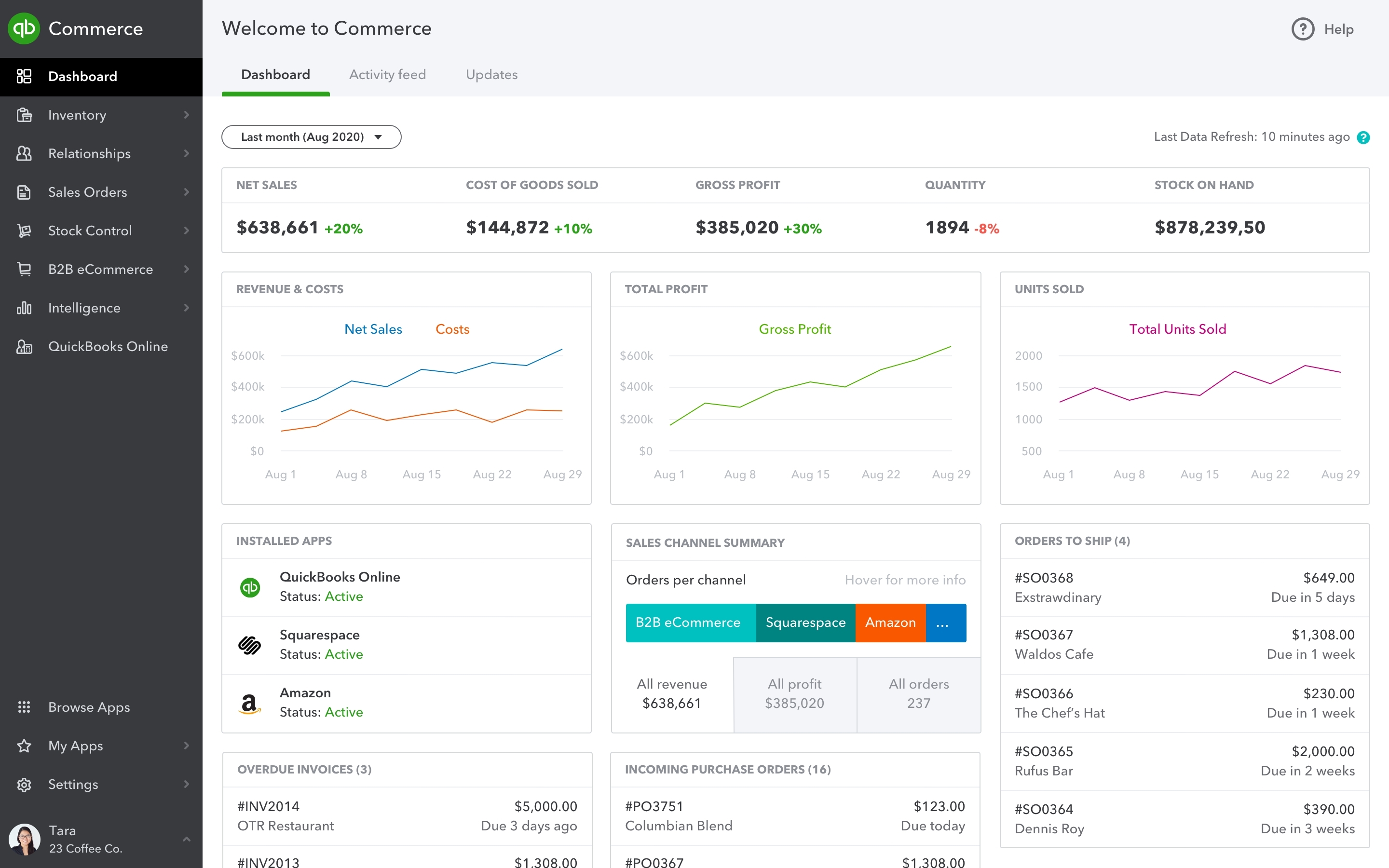

10. QuickBooks Commerce

QuickBooks Commerce integrates accounting, inventory, sales, and purchasing into a single system, syncing directly with online marketplaces and sales channels.

The platform allows companies to connect Amazon, Shopify, and eBay stores with their financial records, giving them centralized control of payouts, invoices, and order management. Businesses can track product volumes, manage stock levels, and maintain accurate reporting without relying on separate systems.

Features:

● Integration with sales channels such as Shopify, Amazon, and eBay

● Syncing of orders, payouts, invoices, and bank deposits

● Multi-channel sales tracking and consolidated order management

● Inventory management with stock tracking and valuation

● Role-based access and support for multiple users

Pricing:

- Simple start: $38

- Essentials: $75

- Plus: $115

- Advanced: $275

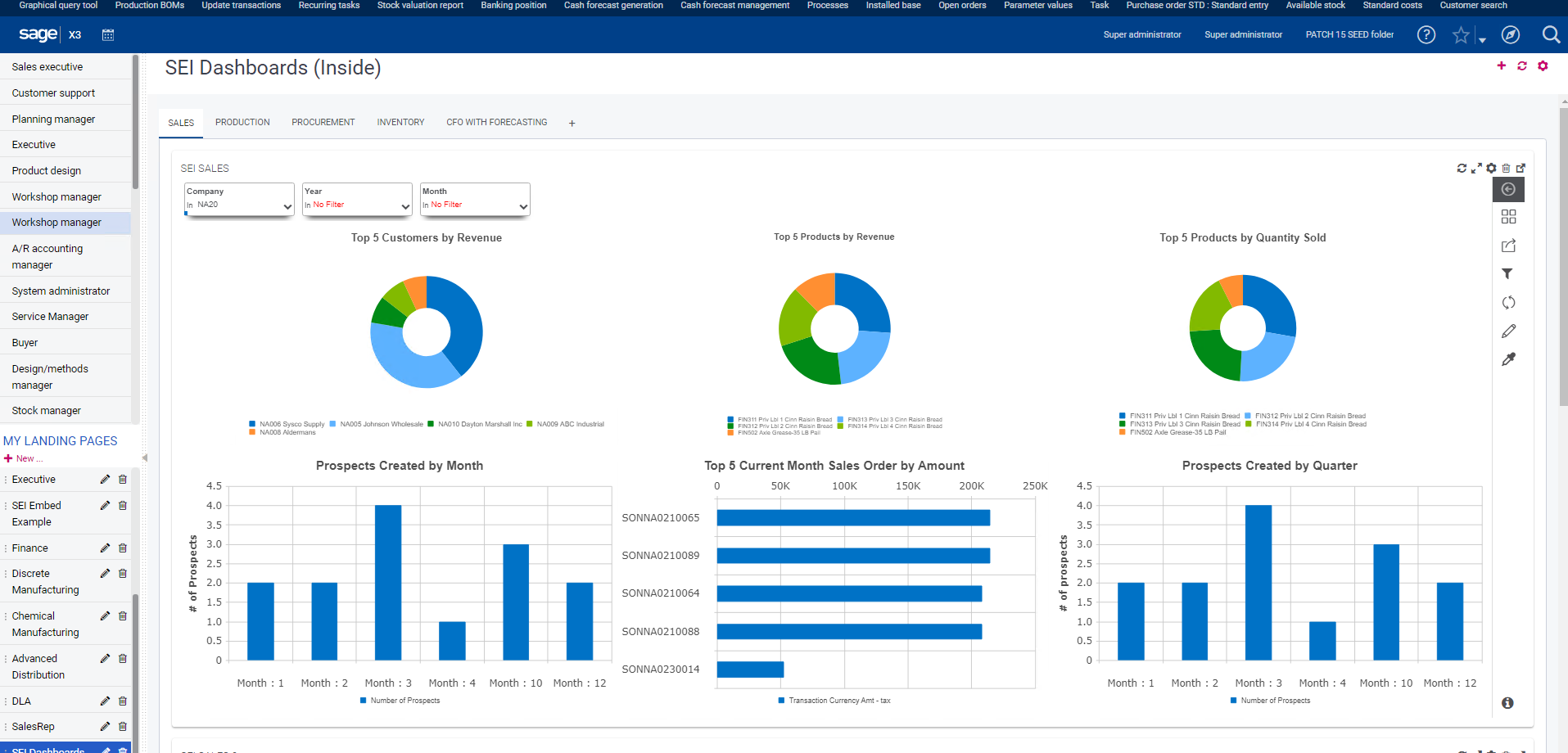

11. Sage X3

Sage X3 is built for food and beverage businesses that need integrated control across production, supply chain, compliance, and finance. The platform provides capabilities for recipe and formula management, lot traceability, allergen reporting, and quality monitoring, helping companies maintain consistency and meet regulatory demands.

The system centralizes purchasing, manufacturing, warehouse, and sales processes and offers multi-country, multi-currency, and multi-legislation functionality. Sage X3 also delivers financial oversight, including cash flow, profitability, and fixed asset management, within the same platform.

Features:

● Recipe and formula management with version control

● End-to-end traceability with recall management

● Allergen reporting and regulatory compliance (e.g., FSMA, SQF, HACCP)

● Inventory and warehouse management with FEFO protocols

● Financial management with multi-currency and multi-company support

Pricing: No public pricing is available.

12. SAP Business One

SAP Business One is a single ERP platform built for small and midsize companies, including food and beverage businesses that need integrated control over accounting, inventory, production, and supply chain processes. It centralizes data and workflows into one system, supporting real-time visibility, traceability, and regulatory compliance while enabling businesses to manage both financial and operational demands within a single solution.

Features:

● Accounting automation for journal entries, accounts receivable, and accounts payable

● Budgeting, cash flow monitoring, and fixed asset management

● Bank reconciliations and payment processing through checks, cash, or transfers

● Financial reporting and analysis with customizable templates and dashboards

● Customer and marketing management with centralized contact data

Pricing: No public pricing is available.

How to Choose the Right Food ERP Software

Selecting the right ERP goes beyond comparing feature lists. The best ERP for you depends on how well the system aligns with your company’s needs.

The best food ERP software should fit your production workflows, compliance requirements, and long-term growth strategy. Before you evaluate specific vendors, take time to examine your business model, challenges, and priorities. Consider these essential factors before making a final decision:

Assess Your Manufacturing Model and Needs

Every food business operates under a specific production model, and your ERP must align with it. Whether you run make-to-stock, make-to-order, batch process, or a mixed-mode operation, the system should support the way you actually produce. For example, process manufacturers that bake, blend, or brew require strong formula management, batch control, and yield tracking to keep recipes consistent and maintain compliance. Even small discrepancies in bills of materials or work orders can lead to waste, recalls, or regulatory issues.

Assessing needs also means looking beyond production methods to daily operational challenges. Perishable products call for features like FEFO inventory management, while businesses handling variable-weight items require catch weight functionality. Quality teams may need more reliable traceability for audits, while finance teams may struggle with cost reconciliation. Engage stakeholders across production, quality, inventory, and finance, to document processes and build a requirements list that ensures the ERP you choose fits your actual workflows and not just generic industry templates.

Determine Implementation Resources

Implementing a food ERP system requires planning for both internal and external resources. Start by identifying who will manage the project inside your organization. This might include an IT lead, operations manager, or a cross-functional team representing production, quality, finance, and compliance.

You should also evaluate the level of vendor or third-party support required. Some ERP providers offer guided onboarding and training sessions, while others expect companies to rely on documentation or outside consultants. Understanding what the vendor includes versus what your team must handle helps you plan budgets and staffing needs. Be realistic about your team’s capacity. If team members are already stretched, consider investing in external implementation partners to ensure you meet deadlines and system configurations align with your compliance and production requirements.

Outline Your Growth Plans

When selecting a food ERP, you need to account for where your company is headed in the next three to five years. If you plan to expand into new regions, launch additional product lines, or grow into ecommerce and direct-to-consumer channels, the system must support those initiatives. Look for functionality such as multi-site management, multi-currency handling, and user permission controls that allow you to manage complexity without relying on siloed systems.

It’s also practical to consider the scalability of modules and licensing. Some platforms offer modular pricing that lets you start with core functions and add advanced capabilities like warehouse management, research and development (R&D), or supply chain forecasting when your operations require them.

Mapping out likely scenarios now, such as an increase in seasonal production or compliance requirements in new markets, ensures you choose a solution that adapts to your business instead of forcing costly migrations later.

Compare Costs

Budgeting for a food ERP requires looking beyond the software license or subscription fee. Implementation often involves expenses for data migration, configuration, training, and ongoing vendor support. You should also plan for recurring costs like annual maintenance, upgrades, and any third-party integrations needed to connect with ecommerce, accounting, or logistics platforms.

Read Customer Reviews

Customer reviews give insight into how ERP systems perform outside of vendor marketing. Focus on feedback from food and beverage companies that share your production model, regulatory requirements, or distribution channels. Their experiences can reveal issues like slow traceability reporting, limitations in recipe management, or how well the vendor supports compliance audits.

Look for patterns across multiple reviews rather than isolated comments. Pay attention to details about implementation timelines, vendor responsiveness, and the quality of training materials. Reviews can also highlight hidden costs, such as add-on modules or integration work. Use these insights to prepare questions for vendor demos and avoid surprises after purchase.

Match Software With Food Manufacturing Industry Requirements

Food manufacturing comes with strict regulations and traceability demands that generic ERPs may not cover. Make a list of the certifications and standards your company follows, such as FSMA, GFSI, or SQF, and verify that the ERP includes tools to support them. Features like allergen tracking, catch weight management, and lot-level traceability aren’t always standard, so confirm that the platform can handle your specific compliance needs without heavy customization.

You should also evaluate recall readiness and reporting capabilities. In the event of a recall, the ERP must trace raw materials, batches, and finished goods back through production and distribution. The system should also provide clear audit trails for regulators and partners. By focusing on industry-specific features, you reduce the risk of gaps that create compliance issues or costly workarounds later.

Choose the Right ERP System for Your Food Business

Selecting the right ERP is a strategic decision for any food company. The system you choose should support your workflows, compliance needs, and growth plans.

Wherefour is purpose-built for food and beverage manufacturers. It supports batch and lot traceability, allergen and nutritional data, and regulatory compliance, including built-in SOC 2 controls. The cloud-based platform works on desktop, tablet, and phone, so teams can use it on the shop floor and off-site.

Whether you manage a small operation or multiple lines, Wherefour provides clear visibility, accurate inventory control, and the flexibility to adapt as you grow.

Schedule a demo to see how Wherefour’s food and beverage ERP supports compliance, traceability, and day-to-day production.

Best Food ERP Software FAQs

How do ERP systems for food manufacturing differ from other ERP software?

ERP systems designed for food manufacturing include capabilities that generic platforms usually lack. These often cover recipe and formulation management, allergen and nutritional data tracking, catch weight handling, and compliance with food regulations like FSMA, SQF, and HACCP.

They also provide detailed lot and batch traceability, recall management, and expiration controls to meet strict food safety and audit requirements. Generic ERPs may require costly customization to achieve the same functionality.

What’s the best food ERP software?

The best ERP software for food manufacturing depends on your business size, production model, and compliance needs. Some companies prioritize advanced financial and supply chain modules, while others focus on batch tracking and quality assurance. The right choice is one that aligns with your workflows, scales with your growth, and reduces the need for custom integrations.

Among food-focused solutions, Wherefour stands out as a purpose-built ERP designed to handle the complexities of food and beverage manufacturing, including traceability, compliance, and flexible process management. It provides clear visibility across production and inventory so teams can respond quickly to operational challenges. The system also supports efficient audits and regulatory reporting, reducing the risk of disruptions and helping manufacturers maintain customer trust.